Center for Direct Reading and Sensor Technologies

Posted on by

The National Institute for Occupational Safety and Health’s (NIOSH) Center for Direct Reading and Sensor Technologies is the centralized hub for all things related to sensor and direct reading technology. The Center coordinates internal and external research to develop recommendations for 21st century sensing technologies in occupational safety and health. Established in 2014, the Center’s work on direct reading methodologies and sensors is based on decades of NIOSH research in this area. The first step towards the creation of the Center was the 2008 NIOSH Direct Reading Exposure Assessment Methods (DREAM) Workshop. Over 175 participants and 12 co-sponsors from academia, labor, management, developers, governmental agencies, and manufacturers participated to discuss the needs of direct-reading methods for assessing occupational exposures.

Background

Direct reading technologies and devices using sensors play an important role in several activities of health and safety in the workplace including detecting the presence of a chemical or physical hazard, identifying a hazardous physical condition, evaluating the performance of work practices and engineering controls, and improving worker engagement via training and awareness. Technologies can provide data by a periodic or continuous process, and the information can be delivered in “real time,” or at the end of a shift. Many monitors can alarm at pre-set hazard levels so that the individual can then mitigate the exposure. Direct reading devices have been used since the early 1900’s. Early examples include the pocket radiation dosimeter patented in 1935 and the noise dosimeter first patented in the 1950s. Modern devices can be used for real-time monitoring of gas and vapor concentration, aerosol concentration, detection of metals via X-ray fluorescence, or detection of methamphetamines, microorganisms, and other kinds of immunologically active contaminants via immunochemical assay kits. Technologies can also be used for assessing physiological conditions such as thermal strain, fatigue, and musculoskeletal disorders.

Highlights

NIOSH researchers have developed several direct-reading methods and real-time monitors in recent years. A few examples include technologies developed for mining environments to monitor respirable dust such as the continuous personal dust monitor and the Helmet-CAM approach and complementary EVADE software. The FAST software allows a, field-based monitoring approach for respirable crystalline silica. Additionally, proximity detection sensors address the co-presence of workers and machines in confined spaces in mining. Monitoring ultrafine aerosols and their chemical composition in real-time using portable handheld instruments is now possible using Aerosol Mobility Spectrometers and Quantum Cascade Laser-IR & Raman analyzers. Sensor arrays, like the Portable Electronic Nose Sampler (MSEM) can allow visualization of different dimensions using modeling and training techniques. Direct reading surface-wipe and field detection technologies have been developed to detect and measure illicit drugs such as methamphetamine and opioids, and anticancer drugs in clinical settings.

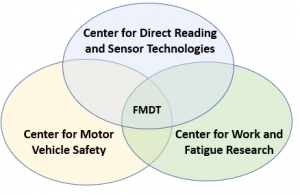

Recently the Center has started an awareness campaign on fatigue monitoring and detection technologies (FMDT) in collaboration with other two NIOSH Centers for excellence: the NIOSH Center for Work and Fatigue Research and the NIOSH Center for Motor Vehicle Safety. Two blogs have been published on the selection of the right technology and its adoption in the frame of fatigue risk management plan.

The knowledgeable selection and adoption of direct-reading methodologies and sensors for health and safety is an aspect of great interest for the Center. The Center released a blog on a framework and initiative called “right sensors used right” in 2018. In 2021, the Center presented professional development courses and scientific sessions at the American Industrial Hygiene Association (AIHA) Conference and Expo, presented virtual webinars for five AIHA local sections on topics related to real-time monitors for aerosols, gas/vapor, noise, fatigue, and wearables. The Center was invited to present a webinar for an online occupational safety and health magazine on wearables and incorporating real-time data to make health and safety decisions. Through these events, the Center has reached hundreds of industrial hygienists.

Wearable sensors, devices that can embrace the true “wear and forget” functionality, have emerged as most recent topic of interest for the Center. A review paper on this topic was recently published (see related blog). These technologies will have an impact on Total Worker Health®. Center staff presented a 2019 webinar exploring the overlap between Total Worker Health, Total Worker Exposure, and Direct Reading and Sensor Technologies. There has been public and media interest in this topic.

External Collaboration

The Center collaborates with several national and international institutions. The recently established Institute for Research in Sensing (IRiS) of the University of Cincinnati has invited the Center to work with a group of PhD students in an interdisciplinary project for exploring novel holistic approaches including sensors for thermal stress in the workplace. The investigation of low-cost sensors for exposure monitoring is the focus of a collaboration with the University of Insubria in Italy. How low-cost sensors can be used for occupational health and safety is also one of the activities of an international collaboration of the Center with the Netherlands Organisation for Applied Scientific Research (TNO) and the Health and Safety Executive (HSE) in Great Britain. The working group has already published a peer reviewed paper on the topic, and it has conducted an internal workshop on the need to transform data from sensors into applicable information and knowledge. This critical aspect of data was already the subject of an early publication by the Center.

We Want Your Input

Finally, the Center is interested in engaging with stakeholders and specifically professionals in industrial hygiene and occupational health and safety to understand the strength and limitations of current practices involving the use of sensor technologies and to discuss the future needs and visions. An anonymous survey, created by the Center, will be open until December 31, 2021 to collect inputs.

As NIOSH celebrates its 50th anniversary the Center for Direct Reading and Sensor Technologies is committed to using our research and products to improve worker safety and health for many years to come.

Emanuele Cauda, PhD, is a Research Engineer in the NIOSH Pittsburgh Mining Research Division and co-Director for the NIOSH Center for Direct Reading and Sensor Technologies.

John Snawder, PhD, DABT, is a Research Toxicologist in the NIOSH Health Effects Laboratory Division and Co-Director of the NIOSH Center for Direct Reading and Sensor Technologies.

This blog is part of a series for the NIOSH 50th Anniversary. Stay up to date on how we’re celebrating NIOSH’s 50th Anniversary on our website.

Posted on by