Respiratory Protection for Workers Handling Engineered Nanoparticles

Posted on by

Introduction

Each day millions of workers in the United States use National Institute for Occupational Safety and Health (NIOSH) certified respirators to reduce exposure to harmful gases, vapors, and particulate hazards. NIOSH has certification, quality assurance, and auditing procedures in place (42 CFR Part 84) that assure purchasers and users that the products they are buying/using have been tested and manufactured to strict standards. When selected, maintained and used in the context of an Occupational Safety and Health Administration (OSHA)-compliant respiratory protection program, in which personal protective technology is part of the hierarchy of controls to protect the worker, respirator users can expect that their respirator is working and reducing the amount of hazards that they could potentially breathe. However, as new hazards emerge, the applicability of the science that NIOSH uses to base respirator test methods, performance requirements, and use recommendations needs to be continually reaffirmed, updated and improved to assure the expected level of protection is provided.

One such emerging hazard is engineered nanoparticles. Engineered nanoparticles are materials with at least one dimension between 1 and 100 nanometers. Because of their distinctive physical and chemical properties, little is known about what possible health effects these properties may have on workers. Previous NIOSH Science Blogs (see the list on the right) and the NIOSH website discussed the health concerns of engineered nanoparticles. Because of these concerns, NIOSH recommends limiting worker exposures to engineered nanoparticles through standard industrial hygiene practices, including respiratory protection (when needed). Although the NIOSH recommended exposure limits (REL) for some types of nanoparticles are based on mass, particle count (number) may be a more significant concern because of their distinctive physical and chemical properties (e.g., increased surface area and reactivity).

The purpose of this blog is to provide an update on the science and rationale behind NIOSH’s recommendations for the use and selection of respirators against engineered nanoparticles.

Respirator Performance Research

While NIOSH has been certifying and conducting research for decades to assure that particulate respirators provide predictable levels of exposure reduction, engineered nanoparticles present new challenges. For example, the current NIOSH certification test for filtration performance (to determine whether a respirator is at least 95, 99, or 99.97% efficient) uses a broad range of particles, including a significant number of nanoparticles, but only measures particles larger than ~100 nm in size penetrating through the filter. In general, because of the challenges in generating and measuring nanoparticles, little research had been done to assess nanoparticle filter penetration and leakage around the face seal area of the respirator. In particular, concerns had been raised that due to their small size, engineered nanoparticles would penetrate through respirators at higher rates than larger particles (so called “thermal rebound” effects).

In 2005, NIOSH initiated a laboratory research program to better understand respirator performance against nanoparticles. As part of that project, NIOSH researchers constructed test systems to generate aerosol challenges as small as 4 nanometers to determine filtration properties of NIOSH-certified and EU marked respirators as well as non-certified dust masks. These experiments were conducted under aggressive conditions (e.g., high flow rates, charge neutralized particles, etc) to assess worst-case situations. Much of this work has been reviewed recently by Shaffer & Rengasamy 2009. In a subsequent study, respirators were donned on a manikin and various sized controlled leaks were created in the respirator face seal to assess whether nanoparticles preferentially leak compared to larger particles (Rengasamy, AOH 2011). In general, these studies found that:

- As predicted by single fiber filtration theory, 4 to 20 nanometer particles were captured very efficiently by respirator filter media, because these small particles are constantly bombarded by air molecules, which causes them to deviate from the airstream and come into contact with a filter fiber to become trapped by the filter;

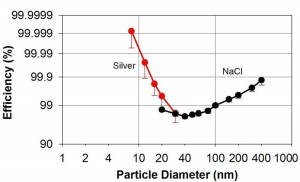

- The most penetrating particle size (MPPS) range (shown in Figure 1) for electret filter media (the most common type of filter used in respirators on the market today) was between 30 and 100 nanometers, with 100-class respirators having higher levels of laboratory filtration performance compared to 95-class respirators; and

- Leak size was the largest factor affecting the number of nanoparticles inside the facepiece of the respirator worn on the manikin, although for small leaks nanoparticles were more likely than larger particles to be found inside the facepiece of disposable N95-class filtering facepiece respirators.

Respirator Selection

The decision to use respiratory protection should be based upon professional judgment, hazard assessment, and risk management practices to keep worker inhalation exposures below an internal control or an exposure limit. The respirator performance research discussed above suggests that NIOSH’s traditional respirator selection tools apply to nanoparticles. There are several types of NIOSH certified respirators (e.g., disposable filtering facepiece, half-mask elastomeric, full facepiece, powered, airline, self-contained, etc.) that can provide different levels of expected protection to airborne particulate when used in the context of a complete respirator program. In a survey to better understand health and safety practices in the carbonaceous nanomaterial industry, NIOSH found half-mask elastomeric particulate respirators to be the most commonly used respiratory protection followed by disposable filtering facepiece respirators. However, this application of respiratory protection appears based on subjective assessment of hazard and risk to high aspect ratio carbonaceous nanomaterials and was before the proposed NIOSH RELs for carbon nanotubes/carbon nanofibers were established.

The 2009 Approaches to Safe Nanotechnology document as well as the Current Intelligence Bulletins on titanium dioxide and carbon nanotubes contain recommendations on respirator use and selection when working with nanoparticles. With the establishment of the proposed RELs for TiO2 and carbon nanotubes, respirators should be selected according to the NIOSH Respirator Selection Logic (RSL 2004) by the person who is in charge of the program and knowledgeable about the workplace and the limitations associated with each type of respirator. As part of the risk assessment process, respirators with 99 or 100-class filters can be selected for workplaces with high concentrations of nanoparticles near their MPPS (50 to 100 nanometers). Furthermore, NIOSH recommends that all elements of the OSHA Respiratory Protection Standard (29 CFR 1910.134) for both voluntary and required respirator use should be followed.

Next Steps

The research done by NIOSH to date has been done in laboratory settings using filtration test systems and manikins under aggressive test conditions. To further validate that its recommendations on respirator use against nanoparticles are optimal, further research is needed in field settings and using human test subjects. Well-designed studies on face seal leakage of nanoparticles, especially workplace protection factor (WPF) studies that validate assigned protection factor (APF) levels for respirators against nanoparticles will be important. Such studies are currently underway.

Ziqing Zhuang, PhD, is the Respiratory Protection Research Team Leader in the Technology Research Branch in the NIOSH National Personal Protective Technology Laboratory (NPPTL).

Mr. Viscusi is a physical scientist in the Technology Research Branch in the NIOSH National Personal Protective Technology Laboratory (NPPTL).

Nano on the website

Approaches to safe nanotechnology

TiO2: Current Intelligence Bulletin

Works Cited

- Dahm, M. M., M. S. Yencken, et al. (2011). “Exposure Control Strategies in the Carbonaceous Nanomaterial Industry.” Journal of Occupational and Environmental Medicine 53(6): S68-S73.

- NIOSH (1995) Respiratory protective devices; final rule and notices. Fed Regist 60(110):30335–30404. Accessed on Sept. 7, 2011.

- NIOSH (2004) NIOSH respirator selection logic. DHHS (NIOSH) Publication No. 2005-100. Cincinnati, OH. http://www.cdc.gov/niosh/docs/2005-100/. Accessed on Sept. 7, 2011.

- NIOSH (2009). “Approaches to Safe Nanotechnology: Managing the Health and Safety Concerns Associated with Engineered Nanomaterials.” NIOSH Publication No. 2009-125. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. Accessed on Sept. 7, 2011.

- NIOSH. NIOSH Current Intelligence Bulletin: Occupational Exposure to Carbon Nanotubes and Nanofibers. November 2010 draft. DHHS (NIOSH) Publication, in draft.

- NIOSH. NIOSH Current Intelligence Bulletin 63: Occupational Exposure to Titanium Dioxide. DHHS (NIOSH) Publication No. 2011160.

- OSHA (1998) Respiratory protection—OSHA. Fed Regist 63:1152–1300.

- Rengasamy, S. and B. C. Eimer (2011). “Total Inward Leakage of Nanoparticles Through Filtering Facepiece Respirators.” Annals of Occupational Hygiene 55(3): 253-263.

- Shaffer, R. E. and A. Rengasamy (2009). “Respiratory protection against airborne nanoparticles:a review.” J Nanopart Res 11:1661–1672.

36 comments on “Respiratory Protection for Workers Handling Engineered Nanoparticles”

Comments listed below are posted by individuals not associated with CDC, unless otherwise stated. These comments do not represent the official views of CDC, and CDC does not guarantee that any information posted by individuals on this site is correct, and disclaims any liability for any loss or damage resulting from reliance on any such information. Read more about our comment policy ».

What confidence do we have that these filtering devices will remove nanoparticles which are much much smaller than 0.3 microns?

Thanks for the question, Mark. We are confident that nanoscale particles (much smaller than 0.3 micrometers) will be trapped by these filters, based on our scientific understanding of filtration performance of particulate filters and respirators for a wide range of particle sizes. Particles larger than 0.3 micrometers are collected by being intercepted, impacted on or settled on the filter material. Particles smaller than 0.3 micrometers are efficiently captured by diffusion mechanisms and trapped by their electrostatic properties. (See: “How do filters collect particles?.”) In addition to this theory-based answer, NIOSH did experiments and showed that particles down to 4 nanometers are captured with an efficiency greater than the rated efficiency of N95 and P100 filters on which they were tested; for example see Figure 1 in this blog (Shaffer and Rengasamy,2009).

What we need is nano fiber protective masks.

I’m lost on the scale of nanoparticles.

one micrometer or micron is 1,000 nanometer. Is that correct?

A TB bacillus can be as small as 3 microns or 3,000 nanometer. The upper respriatory tract, including the turbinates in the nose can capture 50% of particles greater than 10 microns or 10,000 nanoparticles.

Do I have my sizes correct?

Yes, you are correct. One micrometer is 1,000 nanometers.

The most important defence against respiratory hazards is to control the contamination at its source and prevent it from entering the air. This can be done by either substituting dangerous substances with less hazardous ones (particularly where chemicals are used), by isolating or enclosing hazardous operations, or by providing adequate local exhaust ventilation.

Are nano particles as dangerous as asbestos fibres and can fire fighters be exposed via products of combustion normally encountered at structure or car fires?

Breathing apparatus will protect sensitive lung tissue during deployment however my concern is exposures post incident tasking. Is it possible that the numerous known toxic products of combustion may be present in PPE, in trucks and in living environments via aerosol and contamination routes?

If these toxic products were to be collected via station vacuum cleaners, could they be distributed around living areas when using the same vacuum cleaner to clean living areas? Is it appropriate to isolate truck cleaning machines from station cleaning machines?

Nano particles, asbestos and synthetic mineral fibres are all emerging as highly toxic products of combustion with fatal consequences. How should these risks be minimised?

Are nanoparticles as dangerous as asbestos fibers?

Carbon nanotubes have fiber-like shapes and have been studied to see if they behave the same as asbestos. So far there is no direct evidence that carbon nanotubes present the same lung cancer health hazard as asbestos. However, adverse effects have been observed in recent animal studies; it would be prudent to limit exposure where possible.

Is it appropriate to isolate truck cleaning machines from station cleaning machines?

Yes. It is always a prudent practice to segregate cleaning equipment. NIOSH has recommended to nanoparticle manufacturing companies that they use a combination of wet wiping and vacuum cleaning to remove nanoparticles from surfaces. Canister-type vacuum cleaners equipped with HEPA filter cartridges of bags are efficient in collecting nanoparticles. Protective equipment, such as respirator and gloves, should be used when emptying the vacuum cleaner.

Nano particles, asbestos and synthetic mineral fibers are all emerging as highly toxic products of combustion with fatal consequences. How should these risks be minimized?

Using proper protective equipment and following decontamination/cleaning procedures, as described in NFPA 1851 should minimize the risk.

Chuck Geraci,Tom Hales, and Vladmir Murashov contributed to this response.

Found this information…to collaborate and compare the results of this testing:

IRSST – Engineered Nanoparticles: Current Knowledge about Occupational Health and Safety Risks and

Prevention Measures

77

In most situations, unless contraindicated after a detailed analysis of the risks in the work environment, wearing an SAR respirator with P100 cartridge should offer adequate protection. If it is impossible to perform a quantitative risk analysis, the IRSST recommends considering NP dusts to be highly toxic and favours wearing an SAR respirator with very high-performance filters for all potential exposure situations. In situations where this level of protection is still insufficient or there

is an immediate risk to the worker’s health or life, supplied-air respirators or self-contained breathing apparatuses allow maximum protection.

•IRSST. (September 2010). Engineered Nanoparticles: Current Knowledge about OHS Risks and Prevention Measures, 2nd Edition. Report.

The information about particular nanoparticles is very interesting. I have wanted to know the particulars between N95 and P100 respirators and cartridges when it comes to stopping certain particulates in the air. I own a respirator that I used HEPA Respirator), which is for just this type of application. It really comes into the process when individuals have to deal with hazardous gases and particulates in the air all day long. The life of the air filter is rapidly deteriorated and I think the breathing of that person changes over time.

I really have a hard time of approving anything that doesn’t give me 100% because a person’s life is worth more than a few hours on the job. I still don’t understand why people still work so haphazardly in mine shafts across the country. Not only is it dangerous by getting trapped, but you are forced to breathe sparse air that has many particulates and random gases running through it in high concentration.

Workers should use respirators for protection from contaminants in the air only if other hazard control methods are not practical or possible under the circumstances. Respirators should not be the first choice for respiratory protection in workplaces.

Stop dumping this crap into the atmosphere then. If you need a respirator it can’t be good for the whole world!

estimates.

I need to know which laboratories or institutes,,

1,,,,,, I can analyze sample nanocopper ???

2, as the shipping costs as ?? ?? few grams ?? costs, that means ??

3 certify my production in my chili plant as it,,, ?? they can do ??

4, there are instruments that can advise me on my floor to measure the nanocopper ??

5,, you know who can buy what ??

6,, ask of you the maximum of cooperation.

I hope.

oscar trincado

otrin1@gmail.com

chile

skype otrin1000

More protection is needed. Respirators must be used properly and for the right purposes.

My dad is worker in mine field and I think safer policy is need

Thanks for the interesting article Drs. Zhuang and Viscusi. I am a UC Berkeley Chem Bio student and I am working part time as an asbestos building inspector. I am wondering if I should be worried about nano-scale asbestos fibers getting through my PAPR that I use while on the job. I use a 3M PAPR. I am worried about asbestos fibers, particularly those with length between 30 and 100 nm as discussed above. Thanks for your help.

Thanks for the question, Sam. We are confident that nano-scale asbestos fibers will be trapped by high efficiency filters for the PAPR that you are wearing. If NIOSH respirator selection logic (http://www.cdc.gov/niosh/docs/2005-100/) is used to select the appropriate respirators and all elements of the OSHA Respiratory Protection Standard is followed, the PRPR will provide you with adequate protection.

Hi everyone,

This is all new to me, but I was under the impression that nanoparticles are not really particles because they are 1-diensional, and that they act more like a vapour that a particle? For example, rather than depositing on the lungs, they have a tendency to diffuse across the cardiovascular system and migrate into organs. Is there any evidence that combining filters (i.e. P100) with a chemical cartridge reduces exposure levels? Also, allot of the nano particles are Hygroscopic (attract water), so is their a type of filter that could be used to trap the particles in solution?

Thanks for the questions, Jane. Engineered nanoparticles are defined as solid particles that have one or more of their dimension between approximately 1 to 100 nm, and they have heightened or unique properties that are created by their size. smaller than 100 nanometers and solid particles. The smallest nanoparticles, less than 10 nanometers, have a lot of natural motion because of their small size, which is why some may say they may act like gas. What this means is they will follow airflow patterns very easily. However, they are still particles and this high amount of movement actually causes them to collide with filter fibers very effectively. This is why the filter material used in a P100 cartridge is actually very efficient in protecting against exposure to nanoparticles. Combining a P100 filter with a chemical cartridge would not be needed unless the nanoparticle was mixed with or present with a volatile material, such as a solvent, that would require a chemical cartridge.

You asked about 1-dimensional particles, which are becoming popular in nanotechnology research and applications. These materials are known as 2D, or 2 Dimensional materials because they are one atom thick, only about 0.1 to 0.5 nanometers, but could be very large in their length and width. These materials are still particles but look more like sheets or flakes. These materials still behave as particles and they are captured by a P100 filter for all the same reasons a standard nanoparticle would be captured.

Im 34 years old and i work at a ship yard. 3 years ago I inhaled a large amount of a product called active powder 10. I ended up in the hospital with a collapsed lung. It is used as a corrosion inhibitor. I was told it is reactive to moisture. Has any testing been done that can tell me whether it causes health problems. Sine the incident I have been told that I have emphysema. Could it have been caused by this nano product?

Thank you for your question. We are sorry to hear about your health problems. Since we do not know all the clinical details of your case, it is not possible for us to speculate about diagnoses or potential causes. However, we can recommend that an excellent way to learn about potential health issues and precautions for working with industrial products is to review Safety Data Sheets (SDSs) provided by the manufacturer. Based on a Google search, the product you worked with may have been Zerust® ActivPowder™. There are 2 types, ActivPowder-10F and ActivPowder (LS)-10F. Reviewing SDSs provided by contacting the manufacturer, ActivPowder-10F is composed of a trade secret corrosion inhibitor, ammonium benzoate (CAS 1863-63-4), and sodium benzoate (CAS 532-32-1). ActivPowder (LS)-10F is composed of only the latter two ingredients. Of the listed ingredients, ammonium benzoate in particular can be a respiratory irritant, as described in this fact sheet posted by the State of New Jersey: http://nj.gov/health/eoh/rtkweb/documents/fs/0087.pdf. NIOSH also suggests avoiding inhalation of dust containing sodium benzoate: http://www.cdc.gov/niosh/ipcsneng/neng1536.html. We hope this information is helpful.

I would add that many primary, secondary, and tertiary amines can nitrosate to form carcinogenic nitrosamines. ‘Nitrosation of volatile Amines at the Workplace’ onlinelibrary.wiley.com/doi/10.1002/3527600418.mb0b03e0001/pdf is a report that describes how that occurs.

what respirators/masks are commercially available to protect against nanotube/particle inhalation please ?

As mentioned above, the 2009 Approaches to Safe Nanotechnology document as well as the Current Intelligence Bulletins on titanium dioxide and carbon nanotubes contain recommendations on respirator use and selection when working with nanoparticles. Here are the classes of NIOSH approved respirators that can be used to protect against nanotube/particle inhalation: filtering facepiece respirators (N95 or P100), elastomeric half-facepiece, elastomeric full-facepiece with N-100, R-100, or P-100 filters, powered with loose-fitting facepiece, and powered with tight-fitting half-facepiece or full-facepiece. Respirators should be selected according to the NIOSH Respirator Selection Logic (RSL 2004) by the person who is in charge of the program and knowledgeable about the workplace and the limitations associated with each type of respirator. All elements of the OSHA Respiratory Protection Standard (29 CFR 1910.134) for both voluntary and required respirator use should be followed. For specific respirators that are commercially available, please find it from the NIOSH certified equipment list at: http://www.cdc.gov/niosh/npptl/topics/respirators/cel/default.html.

The study of corrosion inhibitor has important practical significance.

Are there home filters that trap the ultra fine particles that come from living less than 500 feet from a freeway?

I have not been able to find one, and I was hoping you had information regarding this technology, if it exists.

I very much appreciate any information provided or if you can point me in the right direction.

Thank you for your comment. Residential exposure control is outside of NIOSH’s areas of expertise and responsibility. That said, ultrafine particles are loosely defined as being 100 nanometer and below (0.1 micrometer). There are standard filter test procedures that establish MERV ratings for heating and air conditioning filters. The acronym “MERV” stands for Minimum-Efficiency Reporting Value. The MERV rating is a measure of the efficiency with which filters remove particles of specific sizes. The standard tests that establish MERV ratings do not evaluate filtration efficiency of particles smaller than 0.3 micrometer. A table describing MERV ratings and common uses can be found at http://www.airpurifierguide.org/faq/merv-ratings. Additionally, a report by Home Energy, http://homeenergy.org/show/article/nav/issues/page/4/id/667, may be helpful to understand the tradeoffs between the increased filter efficiency for high-MERV rated filters and reduced airflow due to increased filter resistance.

Can someone just link to a product I can buy please? I’d also like a vacuum to collect them when they spill. I am working with 70 nm boron nitride and it goes everywhere. This article gives no links to actual tested or suggested products. Any links would b ea good start. Thanks

The 2009 Approaches to Safe Nanotechnology document as well as the Current Intelligence Bulletins on titanium dioxide and carbon nanotubes contain recommendations on respirator use and selection when working with nanoparticles. Because NIOSH is a government agency, NIOSH cannot endorse or recommend specific products. A vacuum designated as a high-efficiency particulate air (HEPA) vacuum should be effective for your task, along with wet wiping. You may want to search on the internet for “nanoparticles HEPA vacuum.” Some suppliers of HEPA vacuums include: Nilfisk, NaceCare and Pullmman-Holt, for example.

“NIOSH rated P100 (HEPA) filter or respirator is only effective for particles 0.3 microns in diameter (300 nm) and above. Since nanoscale concerns itself with dimensions between 1 and 100 nm air filtering respirators may do nothing to eliminate nanomaterials from being inhaled by workers”. Is this a fair statement? If so, what type of filters can be used? What sort of engineering controls would be appropriate?

Thank you for your comment and questions. No, it would not be correct to say that NIOSH-approved filters are only effective for particles 0.3 micrometers and above. It is true that the NIOSH respirator approval criteria involves testing filter performance with 0.3 micrometer particles, however respirator filters do not work like sieves. Particles smaller than 0.3 micrometers are efficiently captured by diffusion and the electrostatic properties of respirator filters.

To test performance with nanosize particles, NIOSH did experiments demonstrating that particles down to 4 nanometers are captured with an efficiency greater than the rated efficiency of N95 and P100 filters. Figure 1 in this blog shows the efficiency between 4 and 400 nanometers (from: Shaffer and Rengasamy,2009).

The type of appropriate engineering control selected should take into account information on the potential hazardous properties of the precursor materials and intermediates as well as those of the resulting nanomaterial. A risk assessment based on your particular circumstances should guide the selection of appropriate engineering controls. NIOSH has developed a series of publications providing solutions for various settings and general guidance. These can be found at: https://www.cdc.gov/niosh/topics/nanotech/pubs.html.

Anybody know any authorized third party or NOISH can issue certificate of nano fiber masks? we wanna apply for it.

If NIOSH receives an application, the nano fiber masks can be evaluated against the regulatory criteria in 42 CFR 84. The nano fiber masks could be issued NIOSH approval if it passed the required certification tests. Please contact NIOSH at PPEConcerns@cdc.gov to learn how to obtain NIOSH approval.

very informative article.

The research conducted by NIOSH on respiratory protection for workers handling engineered nanoparticles is informative and essential. However, I have a question regarding the study’s focus on laboratory settings and controlled conditions. While the findings regarding filtration properties and respirator performance are valuable, how well do these results translate to real-world situations? Are there plans for conducting field studies and using human test subjects to validate the effectiveness of respirators against nanoparticles in actual workplace environments? I believe such studies would provide more comprehensive insights and enhance the practicality of the recommendations provided.

Thank you for your questions. Regarding how well the results translate to real-world situations, filtration results are tested under worst-case conditions and the results can be translated well into workplace conditions. We have conducted simulated workplace studies and published two manuscripts as listed. Due to the difficulty in finding sufficient number of workers handling nanomaterials at a workplace, respirator performance at workplaces have not been conducted.

1. Vo E, Zhuang Z, Horvatin M, Liu Y, He X, Rengasamy S [2015]. Respirator performance against nanoparticles under simulated workplace activities. Annals of Occupational Hygiene 59(8): 1012–1021.

2. He, X., Vo E, Horvatin M, Liu Y, Bergman M, and Zhuang Z [2015]. Comparison of Simulated Workplace Protection Factors Offered by N95 and P100 Filtering Facepiece and Elastomeric Half-Mask Respirators against Particles of 10 to 400 nm. J Nanotech Mater Sci 2(2): 1–6.