Transforming Construction: Automation and Robotics for a Safer Future

Posted on byIntroduction

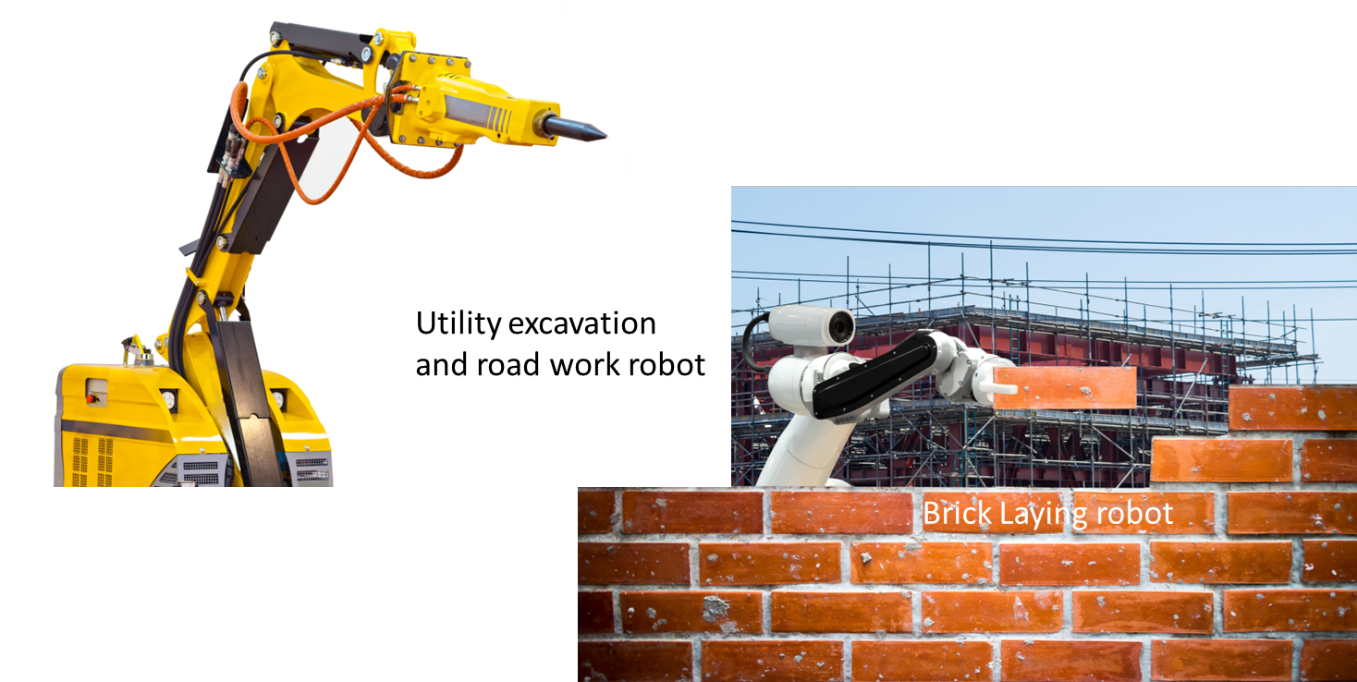

At its core, automation is the use of technology to perform tasks that were once done by humans. Technology includes software, tools to automate workflows, and machinery. Some of the early examples of automation in construction are power tools. As technology progresses, construction automation has seen rapid progress over the last decade with the introduction of robots. These robots can do all sorts of tasks such as utility excavation and roadwork, bricklaying, drywall finishing as well as observation, figure 1.

Robots can handle repetitive and labor-intensive tasks with greater speed and precision than humans. This is advantageous in construction because it can boost productivity, reduce musculoskeletal disorders, and potentially improve the quality of work by reducing human error. However, greater use of robots and automation strategies increase, health and safety concerns.

As exciting as these automation devices are, we need to make sure that they are not creating new and unrealized safety and health hazards. In this blog, we will discuss how NIOSH and other research entities are studying the adoption of automation and robotics in construction, as well as using technology to improve job safety.

Safe Operations of Construction Robots on Human-Robot Collaborative Construction Sites

When robots or automated systems are used on construction sites, they must be able to navigate a variety of safety concerns. These concerns will be much more difficult for construction robots compared to industrial robots because construction settings are swiftly evolving, marked by constant changes in site conditions, project phases, and the introduction of new technologies. These active and ever-changing jobsites create unique challenges for automation, compared to more controlled and predictable environments such as manufacturing. This will require construction robots to have more computational power and advanced sensors to allow for deployment on construction sites and human-robot interaction.

Organizations such as American National Standards Institute (ANSI) and its subgroup the A3 (Association for Advancing Automation) along with the International Organization for Standardization (ISO) have developed and published safety standards ANSI/RIA R15.06 and technical specifications ISO/TS 15066 that have provided guidelines for safe robot operations in controlled settings. These guidelines include:

- Safety-rated Monitored Stop: Robots stop when humans are detected.

- Power and Force Limiting: Robots limit the force they exert to minimize injury.

- Speed and Separation Monitoring: Robots adjust speed based on human proximity.

- Hand Guiding: Direct human control of robots.

These standards are appropriate for robots that work in controlled environments, like manufacturing, and are more difficult to implement on construction sites.

NIOSH researchers presented a paper at the 41st International Symposium on Automation and Robotics in Construction (ISARC 2024) discussing Safe Operations of Construction Robots on Human-Robot Collaborative Construction Sites.

The paper suggests that to keep construction workers safe, it is imperative that energy transfer between humans and robots be managed. This means that if a construction robot does contact a worker, the amount of energy transferred should be low enough to avoid causing injury or pushing the worker out of position. If construction robots can achieve these safe energy transfer limits, it will be a major milestone for deployment, as the risk of injury will be minimized.

The authors modelled two common types of impacts which could occur between robots and construction workers:

- Struck and pushed: A robot’s moving object (an appendage/component) hits and pushes a worker, potentially moving the worker from their position.

- Struck and bent: A robot’s object hits the worker’s back, causing bending at the waist.

It is not safe or practical to test human robot interaction to determine safety limits, thus computer modeling was used. Many different robot factors were included in the model such as, moving speed, angular position, velocity of the joints along with human input factors such as skin and bone properties at different body parts, worker height and weight. These factors can be changed to determine what are safe energy transfers from robots to humans. This modeling approach allows for evaluating specific scenarios and determining what speed a robot can move to keep workers safe should an accidental strike happen.

The authors concluded that human-robot collaboration in construction holds great promise but requires careful attention to safety. Implementing and adapting existing safety standards to the unique conditions of construction sites is crucial. As robotics technology advances, developing specific guidelines and safety measures for construction environments is key to ensuring the safe integration of construction robots.

Even more curious about how robots and humans can work safely together on construction sites? Watch this summary of a December 2023 webinar on “Safe Human-Robot Interaction in Construction”. Experts from NIOSH, the University of Florida’s Rinker School of Construction Management, and others provided exciting and current insights into the state of robots in construction.

NIOSH Center for Occupational Robotics Research

In response to the rapid increase of the use of robotics in the workplace, NIOSH established the Center for Occupational Robotics Research in 2017. The center focuses on enhancing safety in workplaces that use robots. It also monitors injury trends, evaluates robotics technologies, and promotes safety standards. The Center’s work includes studying traditional industrial robots and emerging technologies like collaborative robots, wearable robotics, and AI-driven systems. It partners with industry leaders and universities to advance worker safety and help develop safety standards. For more details, visit NIOSH’s Center for Occupational Robotics Research.

Examining the Use of Drones in Construction

Drones have been deployed on construction sites to conduct mapping and site surveys and monitor work progress. The use of drones has reduced the need for workers to be in dangerous areas. Drones can conduct many processes faster and safer than humans and can improve overall site management. Drone technology has provided many benefits for specific tasks, however safety challenges of human-drone collaboration on job sites remain unexplored. Researchers at the Human-Centered Technology in Construction (HCTC) lab and the Construction Automation & Safety Lab (CASL) in the Rinker School of Construction Management at the University of Florida are working together to understand and mitigate the risks associated with integrating drones into daily construction activities. CPWR the Center for Construction Research and Training has also funded significant research in this area. This video from the University of Florida’s CASL summarizes the use of drones in construction.

NIOSH scientists are studying drone-human interactions on construction sites. Using virtual reality, the study is simulating real-world construction scenarios at height and recording biomechanical responses to drone activity to assess whether the presence of drones increases the risk of acute injury.

Demolition Construction Robots

Demolition robots are seeing rapid growth in construction. Like drones, these robots can complete tasks in hazardous environments that require precise, controlled demolition. This reduces the need for workers to enter dangerous areas. These robots in some cases can work faster than humans and the robots can be outfitted with attachments to complete different types of tasks.

Though these robots are intended to keep workers safe, incidents can still happen. Two workers were seriously injured when they became caught between a demolition robot and a solid structure. Both workers survived, but it is apparent that research is needed to keep workers safe while using robots during construction work. NIOSH scientists are studying how humans interact with demolition construction robots. Researchers are investigating hazards and risk factors (human-related, environment-related, and control-pad interface-related) that may cause operators to place themselves within the hazard area of the robot; that is an area where the operators could get struck by any part of the robot; get caught in, compressed or crushed between parts of the robot and walls, floors, or any other structures; and/or get struck by collapsing structures. In addition, the project is studying human behavior and perceptions of safety and trust when the robot moves unexpectedly while test subjects are operating a virtual demolition robot.

Evolving Automation and Robotics Technologies in Construction

This blog highlighted drones and demolition robots in construction, but these are only the beginning. Many different types and styles of robots are reaching construction sites now and assisting with tasks including brick laying, welding, road paving, and drywall.

In addition to robots, computer programs also are important for construction automation. Programs can help with ordering materials, creating progress schedules or processing payroll. is a group of organizations who are leading in Artificial Intelligence (AI) to sift through construction worksite safety data.

Construction automation takes many forms, with robots among the most common and visible. While we have yet to see full automation across all construction job sites, the robots currently in use are designed to improve both safety and productivity. However, with any new technology comes new and unforeseen risks. This blog highlighted some of the potential injury risks posed by robots and explored how NIOSH and other research organizations are actively working to identify, mitigate, and manage these challenges to ensure a safer future in construction.

Scott Breloff, PhD, is a Senior Biomechanical Research Engineer in the Division of Field Studies & Engineering and the Co-Coordinator for the Construction Program in the Office of Construction Safety and Health at NIOSH.

Scott Earnest, PhD, PE, CSP, is the Associate Director for the NIOSH Office of Construction Safety and Health.

Douglas Trout, MD, MHS, is Deputy Director, Office of Construction Safety and Health at NIOSH.

Asha Brogan, MS, is a Heath Communication Fellow in the NIOSH Division of Field Studies & Engineering.

Marvin Cheng, PhD, is a Team Leader in the NIOSH Division of Safety Research and the Assistant Coordinator of the NIOSH Center for Occupational Robotics Research.

Jacob L. Carr, PhD, is the Team Leader for the Mining Technologies Team in the NIOSH Pittsburgh Mining Research Center and Coordinator of the NIOSH Center for Occupational Robotics Research.

Reference

Cheng, M. H., Liang, C. J., & Dominguez, E. G. (2024). Safe Operations of Construction Robots on Human-Robot Collaborative Construction Sites. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction (Vol. 41, pp. 9-16). IAARC Publications.

Posted on by