Struck-By Injuries in the Construction Sector: Common Hazards, Barriers, and Opportunities to Keep Workers Safe

Posted on byStruck-By Injuries

Struck-by injuries occur from violent contact or impact between an object or piece of equipment and a person. Struck-by injuries can be fatal, and even when a worker is not seriously injured can result in days off work to recover. To help prevent struck-by injuries, companies are encouraged to have a stand-down; a voluntary event for employers to talk directly to employees about safety. This year will be the 4th annual National Stand-Down to Prevent Struck-by Incidents. This event will occur on April 17-21, 2023 with a kick off webinar on April 17 at 2p.m EDT. Understanding the scope of occupational struck-by injuries and prevention solutions is key to understanding the number of incidents that happen each year. Read on to learn more about struck-by injuries in construction and this year’s stand-down.

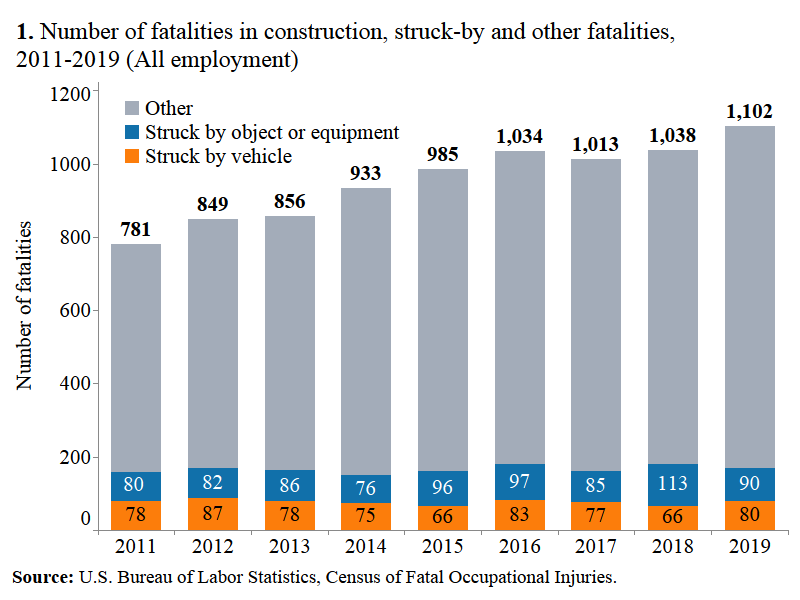

Occupational struck-by incidents caused 150 deaths and 14,000 nonfatal construction sector injuries in 2020 [1]. This totaled $1.4 billion in workers compensation direct costs for non-fatal claims with more than 5 days away from work [2]. Figure 1, from the April 2021 CPWR-The Center for Construction Research and Training Data Bulletin, compares struck-by and other fatalities in the construction industry from 2011 through 2019. During this time, fatalities resulting from being struck by an object or piece of equipment occurred more often (ranging from 76–113 fatalities/year) than fatalities from being struck-by vehicles (ranging from 66–87 fatalities/year).

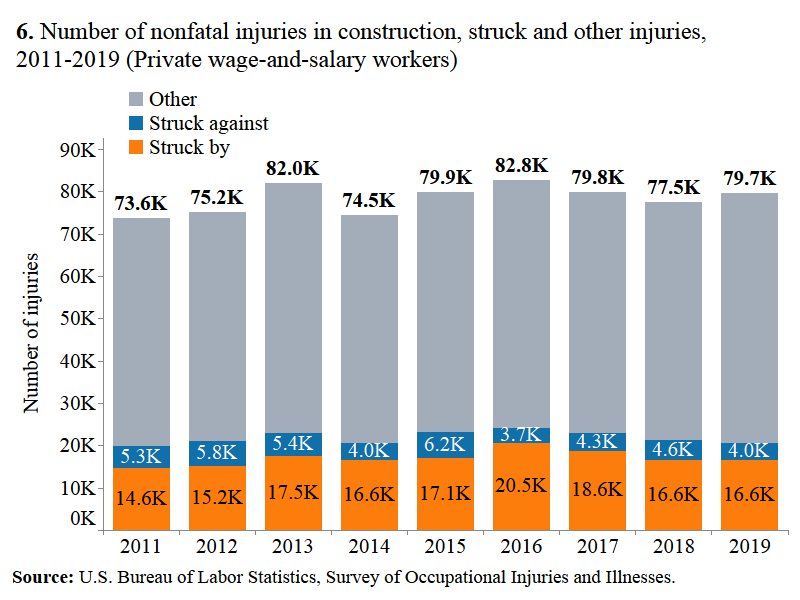

Figure 6 from CPWR shows that during this same period, there were fewer nonfatal struck-against injuries (when the worker strikes the object) (ranging from 3,700– 6,200 injuries/year) than nonfatal struck-by injuries (ranging from 15,200–20,500/year).

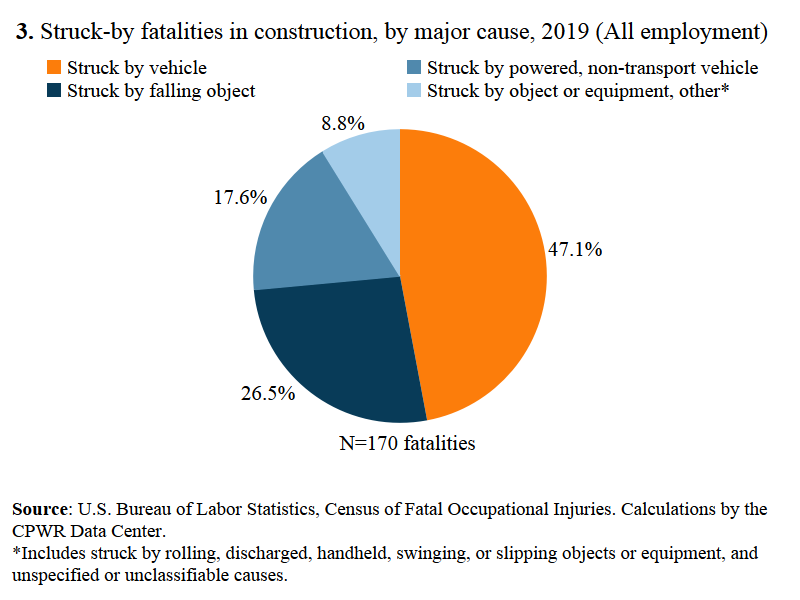

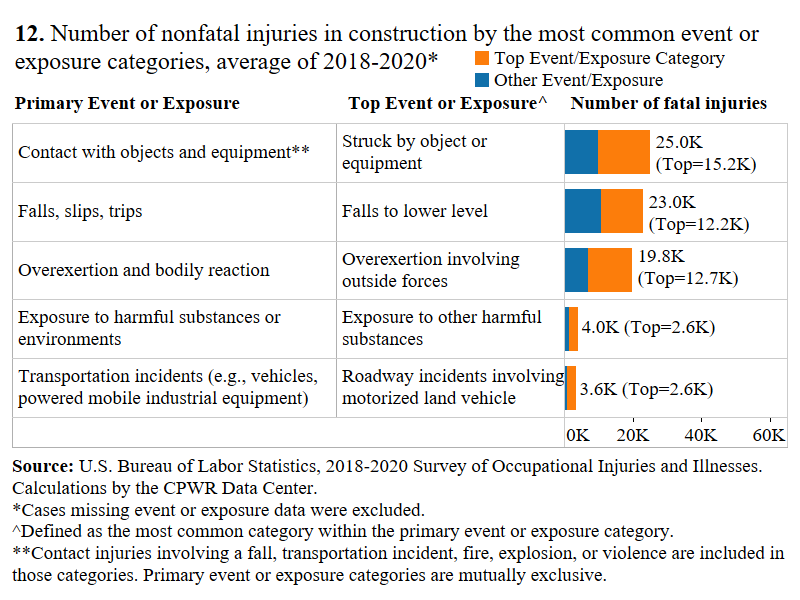

In 2019, struck-by incidents by vehicles accounted for 47% of all construction fatalities, while struck-by incidents by a falling object accounted for 27% of the struck-by fatalities in the same year [Figure 3]. Between 2018 and 2020, interaction with objects and equipment was a key source of nonfatal injuries, with injuries caused directly by striking an object or equipment being the most common averaging approximately 15,200 annually, as is shown in Figure 12 from the CPWR May 2022 data bulletin [3].

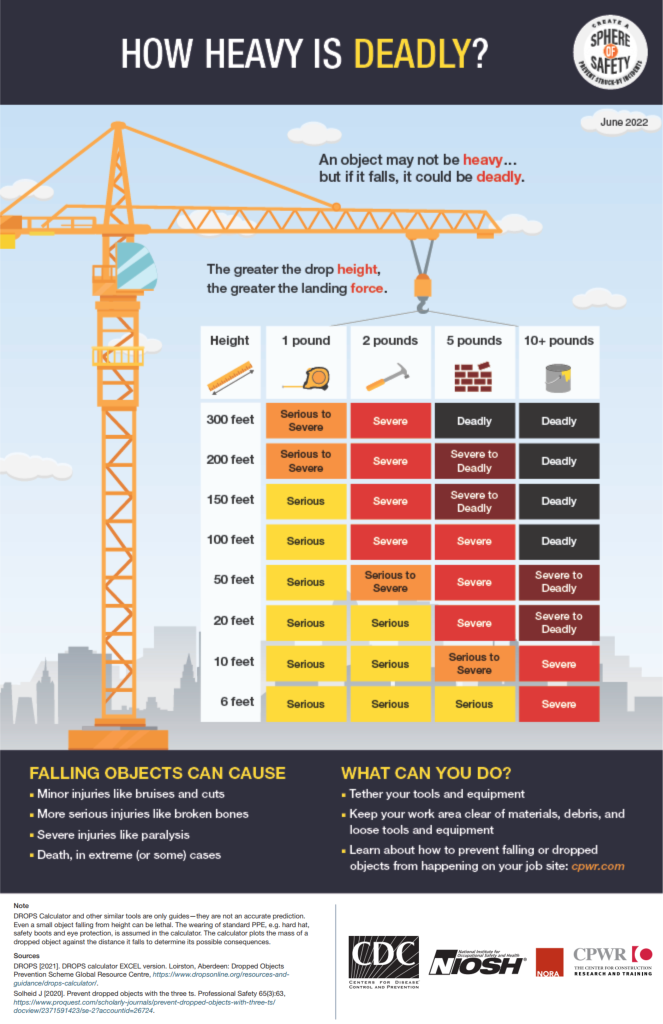

Falling objects pose an inherent risk for struck-by injuries on the job site. Tools, materials, and other objects can fall from roofs, cranes, and scaffolds, but even objects falling from lower levels such as a truck bed or dolly can lead to injuries. Several factors increase the risk of more severe injuries including the shape of the object and where on the body the person is struck. The height at which the object falls and weight of the object are also extremely important, with injury severity increasing as the height and weight of the falling object increase. The infographic, “How Heavy is Deadly” illustrates how falling objects can become deadly.

Falling objects pose an inherent risk for struck-by injuries on the job site. Tools, materials, and other objects can fall from roofs, cranes, and scaffolds, but even objects falling from lower levels such as a truck bed or dolly can lead to injuries. Several factors increase the risk of more severe injuries including the shape of the object and where on the body the person is struck. The height at which the object falls and weight of the object are also extremely important, with injury severity increasing as the height and weight of the falling object increase. The infographic, “How Heavy is Deadly” illustrates how falling objects can become deadly.

To understand how much energy can get imparted onto a worker from a falling object visit Dropped Objects Prevention Scheme Global Resource Centre.

A big percentage of fatal (48%) and nonfatal (20%) struck-by injuries in construction are transportation injuries [4]. Al-Bayati et al. (2023) found that 45% of these injuries were caused by vehicle incursion (when a vehicle hits a worker), where 55% were caused by construction equipment or a fellow crew member [5]. Transportation related struck-by injuries are a serious problem. Researchers reviewed NIOSH Fatality Assessment and Control Evaluation (FACE) reports and gathered recommendations to reduce external and internal source transportation related incidents (Al-Bayati et al., 2022, Table 3 & Table 5, respectively). Internal-source injuries are those incidents caused by a crew member, construction truck, or equipment and external-source injures (also vehicle intrusion incidents) are the incidents caused by non-worker mechanisms such as poor motorist behavior and bad signage. Some examples of these recommendations from these tables are below.

Examples for preventing transportation related external-source incidents include:

|

Examples for preventing transportation related internal incidents include:

|

Understanding Struck-By Injuries in Construction

In 2022, CPWR conducted a survey to improve our collective understanding of effective research to practice (R2P) methods to reduce stuck-by incidents among construction workers.

Survey respondents included 208 construction workers, of which 45% worked in commercial construction. Approximately 3 out of 4 respondents worked for a contractor and almost 9 out of 10 had over 10 years of experience in the industry. According to the survey, the main causes of struck-by injuries included:

- working around heavy equipment or vehicles (36%)

- falling/flying objects from work performed at heights (30%)

- falling/flying objects when working on the same level (19%)

The survey explored differences between worker and employer perceptions of struck-by prevention and found that a lack of understanding on how to address the hazard (27%), scheduling pressures (26%), and a lack of hazard identification and prevention training (23%) were the biggest barriers to implementation of struck-by prevention measures for employers.

The survey found that there were significant differences to the top three barriers workers experienced when engaging in practices that prevent struck-by incidents, including:

- A lack of pre-task planning (30%)

- Too much emphasis on production (22%)

- Lack of training (hazard identification and prevention) (20%)

- A lack of management commitment (12%)

It is important to recognize the common implementation barriers from both the worker and employer perspectives. This helps prevention researchers and safety professionals understand possible gaps in struck-by safety that happen on construction jobsites.

Many companies have overcome these implementation barriers; Of the 208 survey respondents, 148 (71%) indicated their place of employment incorporated struck-by prevention strategies into their project plans. The top three planning activities for companies that deployed them were:

- Conduct job hazard analyses before work begins (91%)

- Conduct job hazard analyses periodically before a new task or type of work begins (83%)

- Conduct/participate in job site meetings before the start of each shift to review struck-by hazards and take steps to prevent incidents, including the location and use of safety equipment, work practices, signage, and who to go to for help (80%)

Respondents suggested that the best training methods for preventing struck-by injuries include: 1) training on how to identify and prevent struck-by hazards (78%), 2) training on how to conduct a job hazard analysis for struck-by hazards (73%), and 3) providing information on what is working on other job sites to prevent struck-by hazards (61%).

In addition to identifying planning strategies to help reduce struck-by injuries, respondents also suggested the best ways to raise awareness of struck-by incidents on construction job sites include the use of communication tools such as toolbox talks and posters hung near hazards or by the entrance to the site.

Respondents suggested several other communication-based prevention methods to help reduce struck-by injuries including: checklists, videos, webinars, and hardhat stickers.

Read the full results for the Struck-by Hazards, Barriers, and Opportunities in the Construction Industry survey. An analysis of the survey results can be viewed as a webinar recording.

Join us & host your own Struck-By Stand-Down

Join us & host your own Struck-By Stand-Down

The National Occupational Research Agenda (NORA) Construction Sector Council is joining with CPWR, OSHA, and other partners on several initiatives to increase awareness and prevention of struck-by hazards, including coordinating the annual National Stand-Down to Prevent Struck-by Incidents.

Join us for the 4th annual National Stand-Down to Prevent Struck-by Incidents April 17-21, 2023. The Struck-by Stand-Down occurs in coordination with National Work Zone Awareness Week. To kick off the stand-down, CPWR is hosting a webinar (click to register) on April 17. Promote this webinar with your employees, then organize and host a stand-down at your jobsite(s). CPWR has many helpful resources regarding struck-by hazards; during your stand-down, decide what communication method(s) work best with the job site and the people who will be working in that area. Have a wonderful stand-down and stay safe!

Scott Breloff, Ph.D. is a Senior Industrial Research Engineer in the Division of Field Studies & Engineering and the Co-Coordinator for the Construction Program in the Office of Construction Safety and Health at NIOSH.

CDR Elizabeth Garza, MPH, CPH, is Coordinator for the Construction Program in the Office of Construction Safety and Health at NIOSH.

Asha Brogan, MS, is a Heath Commutation Fellow in the NIOSH Division of Field Studies & Engineering.

Jessica Bunting, MPH, is the Research to Practice Director at CPWR – The Center for Construction Research and Training (CPWR).

Douglas Trout, MD, MHS, is Deputy Director, Office of Construction Safety and Health at NIOSH.

Mirle Pena, MS, is the Assistant Coordinator for the NORA Construction Sector.

Scott Earnest, PhD, PE, CSP, is the Associate Director for the NIOSH Office of Construction Safety and Health.

Resources

- CPWR Struck-by page

- NIOSH Highway Work Zone Safety Topic Page

- NIOSH Construction Equipment Visibility Topic Page

- NIOSH Fatality Assessment and Control Evaluation Reports

- OSHA Focus Four Training

- OSHA Struck-by Main Page

- The Dropped Object Experiment

References

[1] CPWR Data Bulletin. March 2023. https://www.cpwr.com/wp-content/uploads/DataBulletin-March2023.pdf

[2]Liberty Mutual Workplace Safety Index 2021: Construction. https://business.libertymutual.com/wp-content/uploads/2021/06/2021_WSI_1002_R2.pdf

[3] CPWR Data Bulletin. May 2022. Fatal and Nonfatal Injuries in the Construction Industry. https://www.cpwr.com/wp-content/uploads/DataBulletin-May2022.pdf

[4] CPWR Data Bulletin. September 2022. Fatal and Nonfatal Transportation Injuries in the Construction Industry, 2011-2020. https://www.cpwr.com/wp-content/uploads/DataBulletin-September2022.pdf

[5] Al-Bayati, A. J., Ali, M., & Nnaji, C. (2023). Managing Work Zone Safety during Road Maintenance and Construction Activities: Challenges and Opportunities. Practice Periodical on Structural Design and Construction, 28(1), 04022068.

Posted on by