Preventing Trenching Fatalities

Posted on by

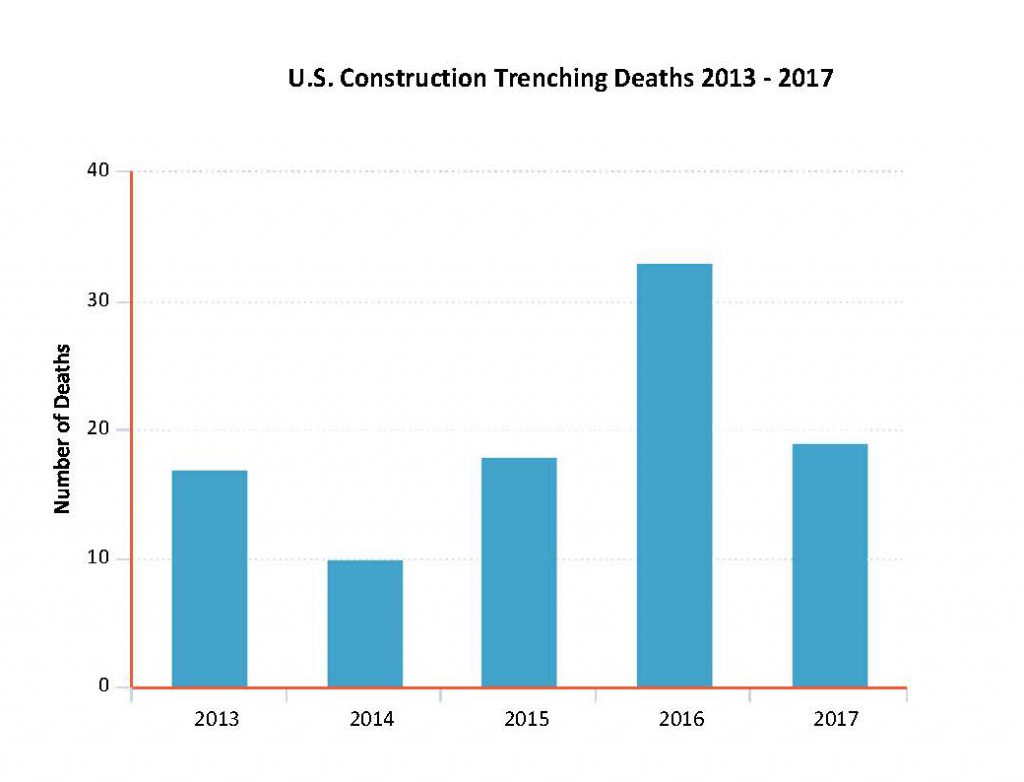

From 2013-2017 there were 97 trenching fatalities in the construction industry – an average of 19 per year, from a low of 10 deaths in 2014 to a high of 33 in 2016 [BLS, 2019]. While the total number of 85 construction-trenching deaths in the previous five years, 2008-2012, was lower, the average of 17 construction-trenching deaths during that five-year period is not significantly different (p=.59) [BLS, 2019]. Furthermore, there was no trend in the number of deaths over the 10 year period 2008-2018 (p=.59).

Alternatives to Trenching

The best way to prevent trench collapse and in turn, trenching fatalities, is to use alternative methods where feasible. A 2016 report prepared for the Environmental Protection Agency, which evaluates methods to rehabilitate drinking and wastewater infrastructure, [EPA, 2016] noted that “new trenchless renewal technologies continue to come to market and improvements in existing technologies are ongoing.” Among the many alternatives to digging a trench are directional boring, relining the pipe (including the technique known as cured-in- place pipe), pipe ramming, and utility tunneling and pipe jacking. The Federal Highway Administration (FHWA) the City of Portland, Oregon, and Iowa State University provide more information about these and other trenchless technologies.

Directional Boring

Directional boring is performed without excavation and with minimal disturbance to the surface if done correctly. The process begins when a directional boring machine pushes a drill bit into the ground at an angle. The drill bit is connected to a hollow pipe. A pressurized jet of drilling fluid flows through the pipe and from the bit. The drill bit and fluid cut through the ground. As the drill bit cuts, additional joints or sections of drill pipe are added as the bit is pushed towards the exit point. When the destination is reached, the bit is removed from the drill pipe. A reamer is connected to the end of the drill pipe if the bore diameter needs to be enlarged. The boring machine retracts the reamer while rotating the pipe. This process is repeated as needed to widen the bore. When the bore diameter is sufficiently larger than the diameter of product pipe, the drill pipe is connected to a reamer, which is joined to the product pipe with a swivel. The boring machine pulls the drill pipe, reamer, swivel, and new product pipe through the bore to complete the job [IDBA, 2019]. While this process eliminates trenching hazards, there are other hazards associated with this work. In 2018, for example, OSHA investigated a directional boring fatality where a worker’s clothing was entangled in an auger [OSHA 2019b].

Relining Using Cured-in-place-pipe

Cured-in-place-pipe (CIPP) is the most popular water pipe repair method used in the U.S. for sanitary sewer and storm sewer pipes. The use of this method is also increasing for drinking water pipe repairs. Relining the pipes eliminates the need for trenching and the associated trenching hazards. Approximately 50% of all damaged pipes are being repaired using CIPP technology. The CIPP procedure involves the chemical manufacture of a new plastic pipe called a CIPP inside a damaged water pipe. While this process eliminates the hazards associated with trenching, the chemicals and processes involved may create new inhalation and dermal hazards (see the related NIOSH blog for more information, including a detailed process description).

Pipe Ramming

Pipe ramming is a trenchless pipe installation technique chiefly used in horizontal applications where an encased piston (the ram) is used to drive a pipe or culvert into the ground with rapidly repeated strikes. The pipe is usually open at the end, unless smaller diameter pipes are being installed. A soil-cutting shoe or bands attached to the pipe guide the soil into the pipe instead of compacting it around the pipe, and enlarges the cut to reduce friction and load on the pipe. Lubricants such as bentonite further reduce friction and ease the movement of the pipe through the soil. When the ram is completed, soil is removed from the interior of the pipe with an auger, by water-jetting, or through blowing with compressed air. Under the right conditions, pipe ramming can be faster and cheaper than directional drilling and other trenchless techniques. Pipe ramming works best for larger pipes over shorter distances (5 to 60 feet) in shallower installations. While pipe ramming can’t be used in solid rock, other soils do not present a problem, and it is well suited for conditions where surface settling may be problematic for other trenchless methods. It has been used to drive steel pipe used to form support for tunnel roofs under existing infrastructure, and can be used to free product pipe or drill pipe that gets stuck during directional boring. [Stuedlein undated; Simicevic & Sterling 2001]

Utility Tunneling and Pipe Jacking

Utility tunneling requires excavations sized to fit the tunneling apparatus at the drive and reception shafts. Preparing those shafts is the first stage of the process. The shafts are typically located at manholes. A concrete slab supports the tunneling equipment and a thrust wall may be needed to provide a solid surface for pipe jacking. An entrance-sealing ring provides a place for the microtunneling machine and pipes to enter the ground. The hydraulic jacking rig is placed and the microtunneling machine is lowered into the drive shaft and onto the jacking rig. The jacking rig thrusts the microtunneling machine through the entrance-sealing ring, and it begins tunneling toward the reception shaft. Excavation is paused when the machine reaches a set position. Trailing hoses and cables are withdrawn and the first section of pipe is readied on the jacking rig. The pipe is thrust to the microtunneling machine, where the two are joined, the cables and hoses are reconnected, and tunneling continues. This sequence of events is repeated as the microtunneling machine tunnels toward the reception shaft. The process is completed when the microtunneling machine emerges at the reception shaft. Finally, the jacking and tunneling apparatus are removed and manholes are built [FP McCann, 2016].

Future Developments

Robots are increasingly common on construction sites [Smith D 2019]. Several years ago, NIOSH funded a feasibility study of a pipe-laying robot [Bernold LE 2005]. In the study, a remotely controlled pipe manipulator was able to transport, line, and joint large pipes thus eliminating the need for pipe layers and helpers to work at the bottom of the trench. A smaller work crew and the elimination of the OSHA requirement to build a protective system should make this approach less costly than conventional trenching [Lee J, Lorenc SJ, Bernold LE 2003].

Prevention

The OSHA standard for excavation and trenching, known as 29 CFR* 1926 Subpart P, describes the precautions needed for safe excavation work. OSHA requires that all excavations 5 feet deep or greater make use of one of the following protective system options : (1) sloping the ground; (2) benching the ground;† (3) shoring the trench with supports such as planking or hydraulic jacks, or (4) shielding the trench (using a trench box). Workers should never enter a trench that does not have a protective system in place designed and installed by a competent person. A competent person is one who understands OSHA regulations, can recognize hazards, and is authorized to correct them. Competent person training is available from many sources, including insurance companies, trade associations, labor unions, trenching safety equipment manufactures, and others.

Planning Before the Job Begins

To prevent trench collapse, planning is required before a job begins. Employers should:

-

- Train and designate a competent person to ensure safety measures are in place.

- Call 811 before digging so that utility lines can be marked, then “pot-hole” utilities to determine the exact location and depth before digging.

- Have a competent person evaluate the soil to determine its stability. Because soil conditions can vary dramatically over just a few days, Appendix A of Subpart P provides techniques (roll test and thumb penetration) for evaluating the condition of the soil.

- Plan the job layout to identify safe locations (away from the trench) for spoil piles and heavy equipment routes.

- Have a competent person determine what type of protective system will be used for the job and schedule the steps needed to have the system complete and in place before workers enter.

- Trenches greater than 20 feet deep can be more complex. The competent person may choose a manufactured protective system with the appropriate depth rating, or use a registered professional engineer to design a site-specific protective system. Refer to 29 CFR 1926 Subpart P for requirements.

- Ensure that none of the workers designated for entry into the trench are under age 18.

- Ensure that workers involved in the job are trained about hazards and work practices in a language that they understand and at the appropriate literacy level.

- Develop a trench emergency action plan [NIOSH 2006] that includes the steps to be taken and provides contact information in case of an emergency. Despite prevention and training efforts, trench collapses continue to kill and injure workers. Please share with us what you view as the barriers to implementing safety measures proven to protect workers and how you think we can overcome them.

CAPT Alan Echt, DrPH, CIH, is a Senior Industrial Hygienist in the NIOSH Office of Construction Safety and Health.

Scott Earnest, PhD, PE, CSP, is the Deputy Director for the NIOSH Office of Construction Safety and Health, Coordinator for the Construction Sector.

CDR Elizabeth Garza, MPH, CPH, is Assistant Coordinator for the Construction Sector in the NIOSH Office of Construction Safety and Health.

This work is a product of the NORA Construction Council. The authors wish to thank members of the Struck-By Work Group for their review and comments.

Additional resources

NIOSH – Workplace Solutions: Preventing Worker Deaths from Trench Cave-Ins.

CPWR – Trench Safety resources.

OSHA – Construction eTool – Trenching and Excavation.

References

Bernold LE [2005]. Final research report: Field studies with innovative safe excavation technology. Raleigh, NC: Construction Automation & Research Laboratory

North Carolina State University. Grant Number: 1 R01 0H04201-01.

BLS [2019]. Census of fatal occupational injuries (CFOI) – Current and revised data. Washington, DC: U.S. Department of Labor, Bureau of Labor Statistics, https://www.bls.gov/iif/oshcfoi1.htm. Date accessed May 16, 2019.

Caterpillar [2019]. 300.9D Mini hydraulic excavator, specifications. Deerfield, IL: Caterpillar, Inc. https://www.cat.com/en_US/products/new/equipment/excavators/mini-excavators/18099279.html. Date accessed May 23, 2019.

Deatherage JH, Furches LK, Radcliffe M, Schriver WR, Wagner JP [2004]. Neglecting safety precautions may lead to trenching fatalities. Am J Ind Med 45:522−527.

FP McCann [2016]. Pipejacking microtunelling animation. Magherafelt, Northern Ireland: FP McCann, Ltd, https://youtu.be/zjXYZAYUYi8. Date accessed May 16, 2019.

GSA . Federal vehicle standards, Standard Item: 9C – SEDAN, COMPACT, 5 PASSENGER, 4 DOOR, 4 CYL ENGINE, minimum requirements. Washington, DC: U.S. General Services Administration, Office of Motor Vehicle Management, Vehicle Purchasing Division https://vehiclestd.fas.gsa.gov/CommentCollector/MinOpt. Date accessed May 23, 2019.

EPA [2016]. Web-based database on renewal technologies. Edison, NJ: U.S. Environmental Protection Agency. National Risk Management Research Laboratory, Water Supply and Water Resources Division, Urban Watershed Management Branch. EPA/600/R-16/086.

IDBA [2019]. The directional boring advantage. Grand Junction, CO: International Directional Boring Association, http://www.directionalboring.pro/. Date accessed May 16, 2019.

Lee J, Lorenc SJ, Bernold LE [2003]. Comparative performance evaluation of tele-operated pipelaying. Journal of Construction Engineering and Management. 129:32-40.

OSHA. Trenching and excavation fact sheet. Washington, DC: U.S. Department of Labor, Occupational Safety and Health Administration, https://www.osha.gov/Publications/ trench_excavation_fs.html. Date accessed May 16, 2019.

OSHA [2019a]. Accident search results. Washington, DC: U.S. Department of Labor, Occupational Safety and Health Administration, https://www.osha.gov/pls/imis/AccidentSearch.search?p_logger=1&acc_description=&acc_Abstract=&acc_keyword=trench&Fatal=fatal&sic=&naics=&Office=All&officetype=All&endmonth=01&endday=01&endyear=2018&startmonth=12&startday=31&startyear=2018&InspNr=. Date accessed May 16, 2019.

OSHA [2019b]. Accident report detail. Washington, DC: U.S. Department of Labor, Occupational Safety and Health Administration, https://www.osha.gov/pls/imis/accidentsearch.accident_detail?id=102569.015. Date accessed May 23, 2019.

Simicevic J, Sterling RL [2001]. Guidelines for pipe ramming. Vicksburg, MS: U.S. Army Corps of Engineers, Engineering Research and Development Center. TTC Technical Report #2001.04.

Smith D [2019]. The robots are coming: Probing the impact of automation on construction and society. Construction Research and Innovation. 10:2-6.

Stuedlein AW [no date]. Pipe ramming research. Oregon State University. http://web.engr.oregonstate.edu/~stuedlea/index_files/Page432.html. Date accessed May 20, 2016.

Posted on by