NIOSH-developed Tools for Monitoring Respirable Crystalline Silica in the Mining Environment

Posted on by

Respirable crystalline silica (RCS), most commonly in the form of quartz, is a known health hazard in many industries. Exposure to RCS can lead to debilitating and incurable diseases. To minimize the risk of health effects associated with exposure, the Mine Safety and Health Administration (MSHA) released a final rule for lowering miners’ exposure to RCS in April 2024. The final rule lowers the permissible exposure limit (PEL) for RCS to the level of the NIOSH recommended exposure limit (REL) of 50 µg/m3 for a full shift, calculated as an 8-hour time-weighted average (TWA) for all miners and creating an action limit of 25 µg/m3. This means that the amount of RCS a miner can be exposed to on average has been reduced approximately by 50 percent.

The rule includes requirements for controlling and monitoring RCS exposures at both coal and metal/nonmetal (MNM) mines. Mine operators regularly conduct hazard and exposure monitoring, but the new rule puts substantially more emphasis on monitoring to ensure effective control of RCS. RCS monitoring is traditionally conducted by collecting a representative air sample with a respirable sampler during a worker’s shift. The sample is then analyzed by an off-site, accredited laboratory to measure the amount of crystalline silica in the sample and determine the associated concentration. While this approach is well-established, a major limitation is the length of time, up to few weeks, it takes for the exposure information to be made available to the mines, limiting how quickly corrective actions can be taken. A second limitation is the lack of details, in terms of time and space, about the hazard and exposure associated with the samples collected.

The NIOSH mining program has performed research in respirable dust and RCS monitoring methods for the mining environment for decades. This includes research to overcome the limitations of the traditional monitoring approach and to provide mine operators with complementary options. This research has resulted in a toolbox of NIOSH-developed solutions for RCS monitoring that are available for implementation at mines.

The NIOSH mining program has performed research in respirable dust and RCS monitoring methods for the mining environment for decades. This includes research to overcome the limitations of the traditional monitoring approach and to provide mine operators with complementary options. This research has resulted in a toolbox of NIOSH-developed solutions for RCS monitoring that are available for implementation at mines.

One such solution is a monitoring approach called Rapid Quartz Analysis (RQA). With RQA, mine operators can perform their own analyses for respirable quartz exposures at the end of a shift. This monitoring approach uses a portable, commercially available instrument (a Fourier-transform infrared spectrometer, or FTIR instrument) and, coupled with a specialized, NIOSH-developed software application, can analyze dust samples for crystalline silica at the mine site on the same day the samples were collected. This technique enables the mine operator to make changes to operations to reduce exposures without having to wait for results when samples are sent to an outside laboratory. RQA is also nondestructive, meaning samples analyzed with this in-field approach can also be sent to an analytical, accredited laboratory for confirmatory analysis.

The NIOSH-developed software required for the RQA approach is called the Field Analysis of Silica Tool (FAST), which can be downloaded free of charge and used with a range of different FTIR instruments. To support and encourage the implementation of the RQA monitoring approach at mine sites, NIOSH has published a comprehensive instruction manual and a complete list of hardware and software requirements. The FAST software translates the raw information from an FTIR portable analyzer into meaningful quartz exposure data, and results are available within a few minutes. Additionally, FAST can track RCS trends over time, enabling faster feedback on the performance of RCS control technologies. RCS results obtained with the current version of FAST are accurate for coal mine samples. For samples collected in mines other than coal, the RCS results should be considered approximations. To improve the accuracy of results for non-coal mine samples, the FAST software can use the results from laboratory analyses of the same samples analyzed with RQA to identify differences between the results from both approaches. FAST then provides a formula to correct the RQA measurements so that they are closer to the laboratory results for future samples.

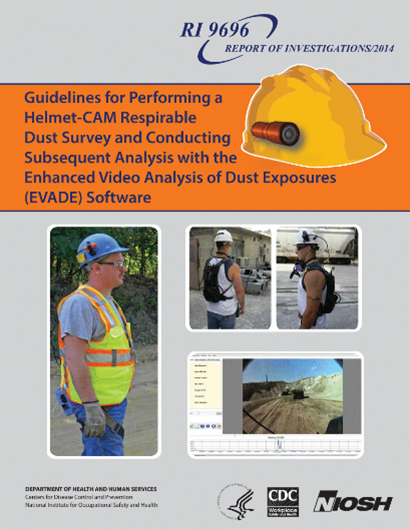

Another tool in the toolbox is a video-assisted exposure monitoring approach called Helmet-CAM although the camera does not necessarily need to be worn on a helmet. Helmet-CAM takes advantage of small and wearable video cameras and respirable dust monitors to assess, during the shift, the evolution in time of the exposure of miners to respirable dust concentration while providing useful contextual information. The camera file provides information about the location of the worker and the type of activity when high levels occur. Through research, NIOSH has found that video cameras can be attached to the helmets of the workers or on the shoulder or chest, transforming basic helmets, vests, and harnesses into smart devices. This monitoring approach is particularly effective for mobile workers who have several tasks during a shift, for the assessment of control technologies and administrative work practices. It is also useful for training, hazard awareness, and risk communication among the work force.

Another tool in the toolbox is a video-assisted exposure monitoring approach called Helmet-CAM although the camera does not necessarily need to be worn on a helmet. Helmet-CAM takes advantage of small and wearable video cameras and respirable dust monitors to assess, during the shift, the evolution in time of the exposure of miners to respirable dust concentration while providing useful contextual information. The camera file provides information about the location of the worker and the type of activity when high levels occur. Through research, NIOSH has found that video cameras can be attached to the helmets of the workers or on the shoulder or chest, transforming basic helmets, vests, and harnesses into smart devices. This monitoring approach is particularly effective for mobile workers who have several tasks during a shift, for the assessment of control technologies and administrative work practices. It is also useful for training, hazard awareness, and risk communication among the work force.

Helmet-CAM uses another NIOSH-developed software, Enhanced Video Analysis of Dust Exposure (EVADE), to extract valuable information and new knowledge about the exposure. The software facilitates the synchronization of the video footage and the file from the respirable dust monitors. The software also allows the simultaneous addition of many channels from videos and dust monitors. The inherent limitation of the Helmet-CAM approach is that the type of personal monitors that provide wearability do not provide specific measurement of RCS. Nevertheless, RCS is a component of respirable dust, and, for this reason, the Helmet-CAM approach can be used to estimate the exposure to RCS. It is important to consider that in some mines, the RCS content is variable in space and time. Mine operators must be aware of this aspect and should consider the complementary nature of the approaches in the toolbox.

Another approach, that employs dust sensing networks (DSNs), allows tracking mine respirable dust levels in time for the identification and analysis of hotspots. While personal exposure monitoring is important for occupational health and safety, area hazard monitoring with DSNs provides valuable information to develop, demonstrate, optimize, and confirm engineering or administrative controls. In recent years, NIOSH has investigated the adaptation of sensors originally used for ambient pollution monitoring to the task of quantifying area respirable dust levels in mines. Field testing has focused on indoor locations like screenhouses, packaging buildings, and drying operations. DSN monitoring technologies are easy to deploy and leverage modern cloud-based computing (data storage, processing, and visualization). The systems tested are generally at a price point that allows for multiple monitors to be used in an area of interest. An advanced use of DSNs combine the data stream with other variables (size/type of material produced, housekeeping frequency, equipment maintenance, etc.) for additional extraction of information and knowledge about the causes of elevated hazard levels. Through its research, NIOSH remains committed to advancing the holistic development of these systems to ensure that they produce data which can ultimately lower the exposure risks for workers. A recent article highlights the utility of the data in a collaborative effort with a midwestern sand operation where the units were in-service for more than a year.

It is important to underline that the three tools described here can be adopted using several commercially available analyzers and monitors and are not limited to one specific product. The users must understand the strengths and limitations of each product and monitoring tool through proper training, education, and analysis of the documentation. This is in line with the approach “right sensors used right” of the NIOSH Center for Direct Reading and Sensor Technologies. NIOSH research is focused on the development of monitoring technologies and methodologies for respirable dust and RCS in mining that can be implemented with different products. NIOSH is also exploring the development of additional tools, such as a sensor that is specific for RCS and can also provide continuous data. Ultimately, the goal is to provide tools for occupational health and safety professionals to monitor and control the exposure of miners to RCS.

Increasing mining companies’ knowledge regarding the respirable dust and crystalline silica levels in their environments and the associated exposure with the aforementioned tools (RQA, Helmet-CAM, DSN), can help them minimize the exposure risks for their workers. The tools described above do not replace traditional monitoring techniques based on laboratory analysis of collected respirable dust samples but rather complement them. The traditional monitoring approach must be used for confirmation and to comply with the proposed regulation. The tools presented in this blog can empower the mining operators in their effort to protect workers, and they can increase the understanding of the hazard and the exposure conditions.

Rachel L. T. Walker, PhD, is a Research Chemist in the NIOSH Pittsburgh Mining Research Division.

Justin Patts is a Mechanical Engineer in the NIOSH Pittsburgh Mining Research Division.

Emanuele Cauda, PhD, is a Research Engineer in the NIOSH Pittsburgh Mining Research Division and Director for the NIOSH Center for Direct Reading and Sensor Technologies.

Posted on by