Celebrating 20 Years of the Nanotechnology Research Center: Highlights from Engineering Controls and Personal Protective Equipment

Posted on by

As the National Institute for Occupational Safety and Health (NIOSH) Nanotechnology Research Center (NTRC) marks its 20th anniversary, we celebrate the creative work of the Engineering Controls and Personal Protective Equipment (PPE) critical topic area, one of the ten critical nanotechnology topic areas of the NTRC. NIOSH researchers have established both research publications and guidance to help reduce worker exposures to engineered nanoparticles and biological aerosol particles. One of the goals of research conducted in this critical topic area is to prevent work-related injury and illness by advancing the state of knowledge and application of PPE. PPE can include, but is not limited to, respirators, gloves, and chemical protective clothing.

The growth of development and commercialization of nanotechnology-based products and applications has contributed to the rapid expansion of the global market as it relates to engineered nanomaterials. The extensive use of these nanomaterials in workplaces has raised concerns about the potential health risks associated with occupational exposure. Thus, NIOSH researchers have conducted laboratory and field research to develop and implement science-based national guidance for respiratory and other PPE to protect against nanomaterial exposures. Major milestones and success indicators of PPE knowledge and advancements include:

1. Evaluating nanoparticles in the early years (Years: 2005-2008):

With increasing concern about health effects associated with the production of nanomaterials and the use of respirators in occupational environments, NIOSH researchers focused on evaluating respirator performance in the nano-sized range.

2. Evaluating respirators against nanoparticles using test subjects (Years: 2012-2015):

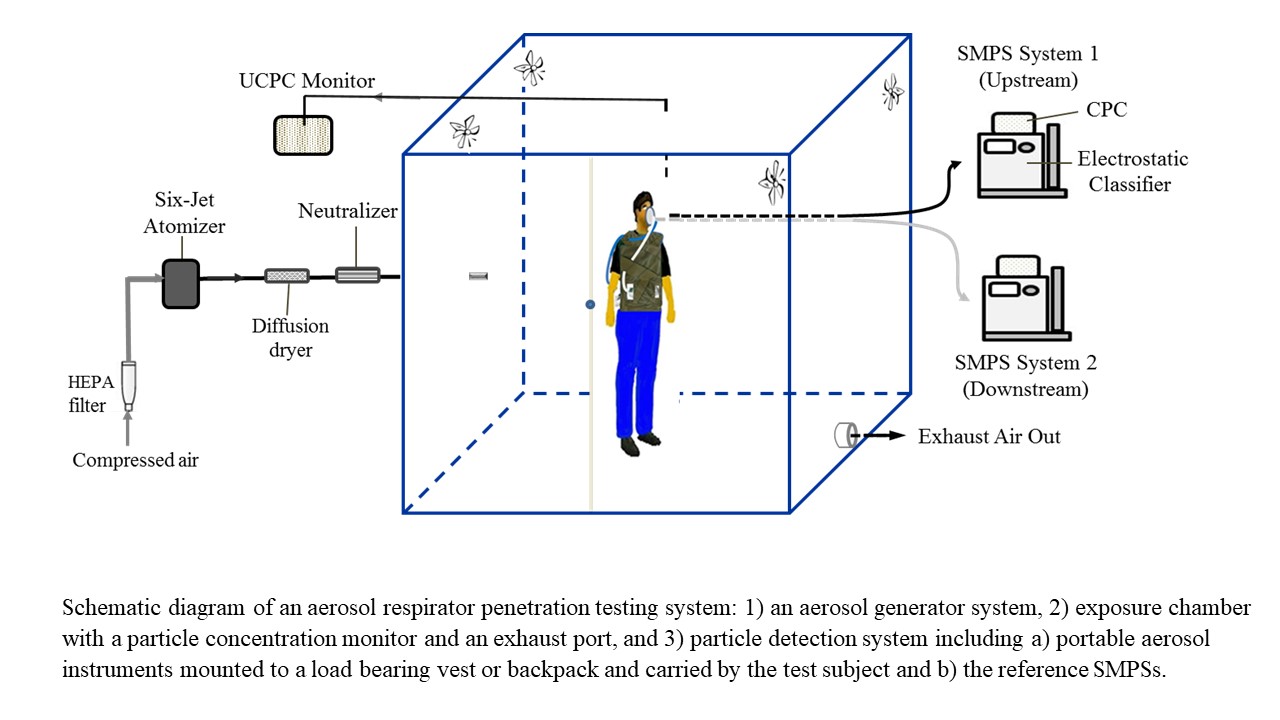

Animal toxicological evidence suggests that a wide range of human health effects could result from exposure to engineered nanoparticles in their workplace (NIOSH, 2013). To address the concerns for nanotechnology, NIOSH researchers have evaluated respirator performance against nanoparticles when worn by human test subjects in order to measure the simulated workplace protection factors for N95® and P100® filtering facepiece respirators and elastomeric half mask respirators as a function of nanoparticle size (20-400 nm size range). This was the first study to measure respirator performance against nanoparticles under simulated workplace conditions and to determine performance differences between respirators with different filter series and different filter efficiency levels (Vo et al., 2015).

3. Using portable instruments while conducting routine work (Year 2014-2024):

Recent advances in aerosol sampling technology have produced new portable aerosol instruments that are smaller and lighter than older ones. To bring new portable instruments to the workplace for sampling, NIOSH researchers developed a new method (Vo et al., 2020) to demonstrate their utility and answer the following questions: 1) how portable instruments can be carried while workers conduct their routine work and 2) how portable instruments can withstand a working environment (including bending, side-to-side reaching, and other movements). This new method allows for measuring respirator performance against aerosol particles in simulated workplace settings.

Looking Ahead

Respirators are commonly used by workers for protection against potentially hazardous particles; however, respirators are typically selected based on manufacturers’ recommendations or laboratory penetration testing data using spherical shape particles. These tests are not applicable for the elongated-shape particles of nanomaterials because both spherical-shape and elongated-shape particles have different penetration mechanisms due to their rotation time, interception, and inertial impaction. For these concerns, NIOSH researchers plan to 1) Develop a new reliable aerosol testing method that can accurately evaluate the respirator penetration against workplace nanomaterials, 2) Evaluate the effectiveness of NIOSH-approved® respirators to determine whether existing respirator guidelines apply to workers exposed to nanomaterials, and 3) to compare nanomaterial penetrations determined by direct-reading and elemental carbon (EC) analysis methods.

How You Can Get Involved

We’ve only seen the beginning of the development and use of engineered nanomaterials. NIOSH researchers continue to provide assistance and help workers to prevent work-related injury and illness by advancing the state of knowledge and application of PPE. If you have any insights or suggestions about PPE research needs, relating to nanomaterials or advanced materials, please contact us at nano@cdc.gov or feel free to share your thoughts in the comment section below. To explore more of NIOSH’s work in Nanotechnology and Advanced Materials, please visit www.cdc.gov/niosh/topics/nanotech.

Evanly Vo, PhD, DDS, Physical Scientist (NTRC-PPE Coordinator) in the Research Branch, National Personal Protective Technology Laboratory.

Michael Bergman, MS, Biologist in the Research Branch, National Personal Protective Technology Laboratory.

Ziqing Zhuang, PhD, General Engineer in the Research Branch, National Personal Protective Technology Laboratory.

This blog is part of a series to commemorate the 20th anniversary of the Nanotechnology Research Center. Click here for additional blogs in the series and on other nanotechnology topics.

A selection of the NTRC PPE products (Peer-reviewed publications)

- Rengasamy, A., R. Verbofsky,W.P. King, and R.E. Shaffer: Nanoparticle penetration through NIOSH-approved N95 filtering-facepiece respirators. Int. Soc. Resp. Prot. 24:49–59 (2007).

- Rengasamy S, KingWP, Eimer B et al. (2008b) Filtration performance of NIOSH-approved N95 and P100 filtering-facepiece respirators against 4–30 nanometer size nanoparticles. J Occup. Environ Hyg; 5: 556–64.

- Vo, E., Rengasamy, S., Shaffer, R. (2009). Development of a test system to evaluate decontamination procedures for viral droplets on respirators. Applied and Environmental Microbiology, 75, 7303-7309.

- Fisher, E., S. Rengasamy, D. Viscusi, E. Vo, and R. Shaffer. 2009. Development of a Test System to Apply Virus Containing Particles to Air Permeable Materials for the Evaluation of Decontamination Procedures for Filtering Facepiece Respirators. J. Appl. Environ Microbiol. 75:1500-1507.

- Evanly Vo, . (2015) Occup. Hyg., Vol. 59:1012–1021.

- Evanly Vo, Matthew Horvatin, Michael Bergman, Bingbing Wu, Ziqing Zhuang, A technique to measure respirator protection factors against aerosol particles in simulated workplace settings using portable instruments” in Journal of Occupational and Environmental Hygiene, Volume 17, Issue 5, 2020, p. 231-242.

- Evanly Vo, Samy Appavoo, Susan Xu, Matthew Horvatin, and Ziqing Zhuang, “New technique to evaluate decontamination methods for filtering facepiece respirators”. American Journal of Infection Control. Volume 49, Issue 4, 2021, p. 416-423.

References

- NIOSH (National Institute for Occupational Safety and Health). (2013) NIOSH Docket Number 161A. Current Intelligence Bulletin 65: Occupational Exposure to Carbon Nanotubes and Nanofibers.National Institute for Occupational Safety and Health. DHHS (NIOSH). Available at: http://www.cdc.gov/niosh/docket/archive/docket161A.html

- Evanly Vo, . (2015) Occup. Hyg., Vol. 59:1012–1021.

- Evanly Vo, Matthew Horvatin, Michael Bergman, Bingbing Wu, Ziqing Zhuang, A technique to measure respirator protection factors against aerosol particles in simulated workplace settings using portable instruments” in Journal of Occupational and Environmental Hygiene, Volume 17, Issue 5, 2020, p. 231-242.

Attribution statement

- N95 and NIOSH Approved are certification marks of the U.S. Department of Health and Human Services (HHS) registered in the United States and several international jurisdictions.

- P100 is a certification mark of the U.S. Department of Health and Human Services (HHS) registered in the United States.

Posted on by