Hazardous Exposures to Silica in Metal and Nonmetal Mining Indicate the Need for Better Prevention

Posted on by

Mined raw materials, or products produced from them, are essential for all industries. Mining will remain an essential industry even with the shift to sustainable energy as critical minerals that will support the needs for zero-emission vehicles, carbon-free energy, and production of energy resources and everyday products must be mined. Respirable crystalline silica (RCS) is one of the most prevalent and severe health hazards in mining – one that has been well-known since the Hawks Nest Tunnel Disaster in 1930. A recent paper from the National Institute for Occupational Safety and Health (NIOSH) details the persistence of hazardous RCS exposures among workers in metal and nonmetal mines 2000-2019. In 2021, these non-coal mines were 92% of the 12,567 active mines in the U.S (Mine Safety and Health Administration – MSHA). The NIOSH paper highlights the need for additional preventative measures and future research to guide public health decision-making and protect mine workers from RCS.

Respirable Crystalline Silica

Silica is the most common mineral on earth and its crystalline form (often know as quartz) exists in most mined materials, such as metal ore, stone, sand, and gravel. RCS occurs when minute airborne particles originating from silica-containing rocks and products are generated during mining activities, including (but not limited to) rock drilling, blasting, grinding, polishing, crushing, sawing, and material transfer. When inhaled, RCS can lead to silicosis, an irreversible lung disease characterized by lung inflammation and scarring that can progress to the most severe form, progressive massive fibrosis. Workers exposed to RCS are also more likely to develop lung cancer, chronic obstructive pulmonary disease, and chronic kidney disease.

Regulations

The hazardous and ubiquitous nature of RCS presents a need for effective control strategies. In 1974, NIOSH established a recommended standard to prevent workers developing silicosis or other functional lung impairments. It suggested a range of controls including a recommended exposure limit (REL) of 50 micrograms per cubic meter of air (μg/m3) calculated as a time-weighted average for up to a 10-hour work day and a 40-hour workweek. At about the same time, the Mine Safety and Health Administration (MSHA) adopted a permissible exposure limit (PEL) for RCS, requiring that exposure to respirable dust containing >1% quartz not exceed an effective RCS equivalent exposure of 100 μg/m3 calculated as an 8-hour time-weighted average per work shift. On June 30, 2023, MSHA proposed a new silica rule for all mines to require use of engineering controls, administrative controls, exposure monitoring, and medical surveillance, and lower the PEL to 50 μg/m3 calculated as an 8-hour time-weighted average per work shift.

Research

Through the NIOSH Miner Health Program NIOSH received input from partners about the need for better worker exposure assessment data for RCS, particularly in metal and nonmetal mines. NIOSH recently analyzed RCS exposure data from MSHA’s health inspections in metal and nonmetal mines. Specifically, researchers were interested in evaluating and describing the mine types, commodities, mine locations, years, and occupations in which exposures exceeded REL and PEL levels over a 20-year period.

Results of NIOSH analysis of MSHA health inspection data from 2000-2019 include:

- Mine workers’ overexposures to RCS were prevalent throughout the 20 years;

- Workers’ overexposures to RCS occur in both surface and underground metal and nonmetal mines, and varied across several factors (e.g., location in mine, occupation, etc.); and

- Overall, the mean full-shift RCS exposures in metal and nonmetal mines increased noticeably in 2018 and 2019, while the number of samples collected was substantially less than in prior years.

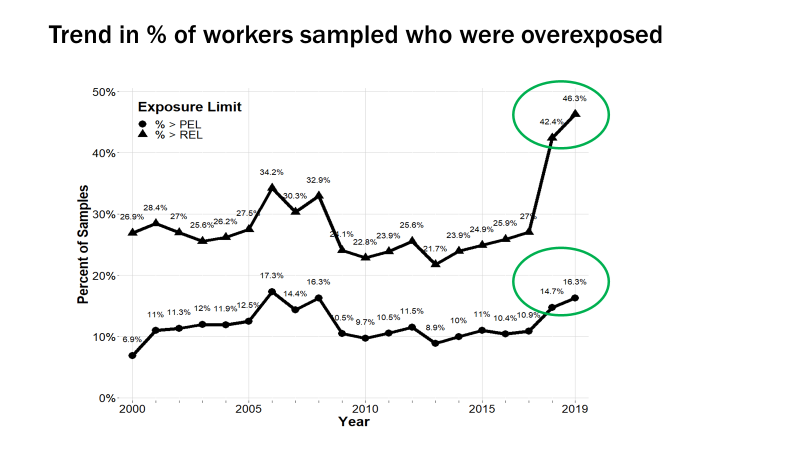

Among the more than 55,000 samples of workers’ personal full-shift exposures to RCS collected by MSHA between 2000-2019, 11.8% exceeded the (1974) MSHA PEL and 27.3% exceeded the NIOSH REL. The maximum RCS exposure measured was more than 40 times greater than the MSHA PEL. Over the entire 20-year period in individual mines that MSHA sampled for RCS, 28% had only one sample collected and the median number of samples was three. As a result, these data do not allow for statistical assessment of the acceptability of or trends in RCS exposures in individual mines. Additional sampling would be required for those purposes.

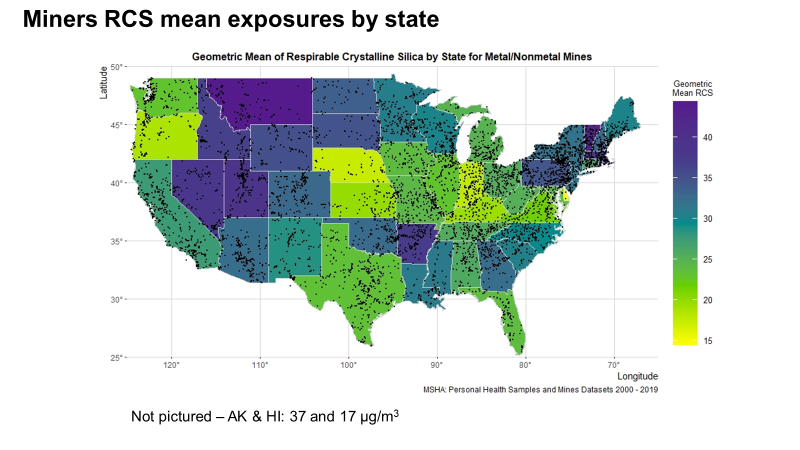

- Among all mines sampled over the past 20 years, the miners’ average full-shift exposure to RCS (47.8 μg/m3) was consistently high over the past 20 years, nearly equal to the NIOSH REL.

- The percent of workers sampled that were overexposed to RCS during 8 hours of their work shift increased dramatically in 2018 and 2019, warranting further study. (Figure 1)

- Miners’ personal exposures to RCS varied significantly with commodity, occupation, mine type, mine location, and state (figure 2).

Next Steps

These results indicate a need for better silica control in metal and nonmetal mines to prevent silicosis, lung cancer, and other occupational diseases.

There is also a need for increased sampling in individual mines for exposure assessment. Under MSHA regulations this is the mine operator’s responsibility.

NIOSH has researched many silica dust engineering controls for metal and nonmetal mines (Photo 1) and has recommended solutions demonstrated to be highly effective in reducing overexposures. Additional research on these interventions is needed to assure wider implementation of effective engineering controls in non-coal mining to minimize miners’ future risk of acquiring progressive diseases.

For more information:

Dust Control Handbook for Industrial Minerals Mining and Processing Second Edition – NIOSH

Aaron L. Sussell, PhD, MPH, CIH®, is an Epidemiologist in the NIOSH Spokane Mining Research Division.

Samantha E. Wilson, MS, is a Research Statistician in the NIOSH Spokane Mining Research Division.

Alexander Johnson, MPH, is a former Health Communications Specialist in the NIOSH Spokane Mining Research Division.

Posted on by