Prevention of Injuries and Fatalities Involving Overturn of Drill Rigs and other Specialty Equipment for Foundation Construction

Posted on by

Introduction

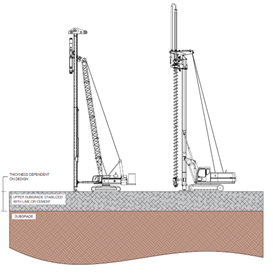

Every year, drill rigs and other heavy, specialty equipment used for deep foundation construction (Figure 1) overturn potentially causing injuries and fatalities, as well as damage to the surrounding sites. There are many safety hazards associated with working around this heavy equipment, including the “Focus Four Hazards”: falls, caught-in or -between, struck-by, and electrocution. However, the overturn of drill rigs and similar heavy equipment used for deep foundation construction can be considered an ‘emerging hazard’ because: (1) the circumstances and environments in which this heavy equipment is used for deep foundation construction vary over time and by location; and (2) data needed to better understand factors contributing to these equipment overturn incidents are incomplete.[1] This blog aims to raise awareness on this emerging hazard and provide guidance from existing resources while additional research and prevention efforts are explored to prevent injuries and fatalities from overturn of drill rigs and other equipment used for foundation construction.

Examples of Incidents

Chicago, Illinois

In an incident in Chicago in 2021 (Figure 2), a 100-ton hydraulic drill rig toppled over knocking down power lines and striking a vehicle. Homes in the area were evacuated and power was shut off leaving residents without power. Fortunately, there were no reported injuries. The drill rig was drilling from its least stable position (perpendicular to the crawler tracks) on a narrow, elevated platform.

Philadelphia, Pennsylvania

In an incident in Philadelphia in 2021, a 75-ton drill rig was being used as a crane to transfer large diameter steel pipes from a flatbed truck using the auxiliary winch. The drill rig was not in the proper configuration for hoisting when the drill rig toppled. It fell in the direction of the suspended load, striking and killing a construction worker on the ground and injuring the drill rig operator. The operator was not NCCCO drill rig certified. The drilling company was cited four times by OSHA for this incident.

Background

In construction, the foundation is the lowest part of a structure that creates stability by transferring loads from the structure to the ground. Deep foundations transfer the weight of buildings, bridges, or other structures deep into the earth (often into bedrock) to provide firm and stable support. Foundation drill rigs are used to install vertical and horizontal longitudinal elements for many types of projects, including deep foundations, retaining-walls, slurry-walls, soil improvements, and bulkheads or seawalls.

Most deep foundation equipment is track mounted, has tall masts and powerful hydraulic motors that can drill deep, large diameter holes. Some of the larger equipment is built on a crane chassis where the crane boom is removed and replaced with a vertical mast. Modern drilling equipment has become heavier as the demand for deeper and larger diameter foundations increase, requiring more powerful equipment. New classes of rigs often exceed 150 tons and can reach 280 tons, with uniform ground pressures that routinely exceed 4,000 pounds per square foot.

What is Known About the Causes of These Incidents?

Contributing factors to these incidents include poor working platforms and improper use of the equipment.

Poor Working Platforms

Often, pressures exerted by drill rigs on soil subgrades exceed the loads that will be produced by the completed building. However, the working subgrade beneath heavy equipment (the working platform) may provide unsuitable support for the equipment and cause an overturning incident. Proper design of working platforms is based on understanding:

- The maximum surface slope a drill rig can safely travel on or work from

- Bearing pressures a drill rig will exert

- The support capability of the subgrade

- The potential for old utilities and other subsurface anomalies

- How to manage these pressures and slope on a working platform.

Contributing factors include: soft soils, improperly compacted back fills, underground utilities, voids or tanks, as well as movement up and down slopes. Well-designed ramps and access to the platform are important considerations. It is equally important to ensure appropriate monitoring, maintenance, and repair of the working platform during use.

Improper Use of Equipment

The primary function of a drill rig is to excavate shafts rather than move materials like a crane. Many drill rigs have an auxiliary winch to assist in operations such as handling reinforcing cages or tooling. Despite being able to move some materials, many manufacturers warn operators that the drill rig is not a crane. Drill rig masts are close to vertical and drill rig design significantly limits the hoisting ability. Operators are expected to follow the manufacturer’s guidelines for lifting capacities and mast angles in addition to developing and using a safe lifting plan to avoid significant accidents.

Not only is there a risk to employees working on a jobsite, but the public as well. For example, in another incident (Figure 3), the drill rig operator was injured, but also overhead power lines for a commuter train were damaged and stopped service. The liability costs of these incidents can be staggering.

Ongoing Efforts to Improve Prevention

The Deep Foundations Institute (DFI), the International Association of Foundation Drilling (ADSC) and the Pile Driving Contractors Association (PDCA) have established an Industry-Wide Working Platform Work Group to improve design and safe construction practices for deep foundation installation.

In 2017, DFI conducted an informal survey of approximately one hundred DFI contractor members regarding working platform safety. The survey showed that a high percentage (88%) of respondents believe that inadequate working surfaces have been a major cause of overturned cranes, drill rigs, excavators, and other heavy equipment. Inadequate working platforms are categorized as:

- Slick (little or no traction)

- Too steep for equipment to safely travel

- Inadequate bearing resistance causing rutting and instability of deep foundation equipment.

Available Guidance

Some aspects of developing safe working platforms for deep foundation drilling are discussed in OSHA 1926 Subpart CC for Cranes and Derricks. Specifically, there is relevant language in 1926.1402 related to appropriate ground conditions for heavy equipment, although there are currently no regulations in the United States directly addressing working platforms. There is also guidance in American National Standards Institute (ANSI)/American Society of Safety Professionals (ASSP) Consensus standards A10.19 (Safety Requirements for Pile Installation and Extraction Operations), A10.23 (Safety Requirements for the Installation of Drilled Shafts), and A10.30 (Safety Requirements for the Installation of Ground Anchors and Micropiles). The Province of Ontario, Canada passed legislation in 2016 addressing working platform safety for large rotary foundation drill rigs.

Best practices available from the trade associations and in the ANSI/ASSP guidance to promote use of safe working platforms include:

- Conducting a Geotechnical Report of existing conditions with soil borings and anticipated soil bearing pressures

- Pre-Construction meetings to discuss equipment limitations, required ground conditions, and activity sequencing

- Pre-inspection of soil conditions before equipment mobilization

- Regular inspection and evaluation of soil conditions, continual remediation as necessary

The ADSC-IAFD, PDCA, and DFI produced a Guidance Document on Safe Working Platforms in 2019. This document takes a Prevention through Design approach and addresses several areas important for safe working platforms:

- Recognition of the need for proper analysis and preparation of working platforms by controlling entities and acknowledgment of responsibility for such tasks

- Recognition of the need for more investigation into old and/or remnant structures in urban cond

itions

itions - Common use of appropriate contract language for prime contracts and subcontracts

- Enforcement through industry consensus.

One of the most important proactive measures advocated for in the document is the establishment of standard, thorough communication procedures to be utilized by the foundation subcontractor, the general contractor, and the controlling entity. Good communication is identified as one of the most crucial factors needed to ensure the evaluation, construction, and use of safe working platforms. In addition, the European Federation of Foundation Contractors (EFFC) and DFI formed a working platform task group that has developed a joint Guide to Working Platforms which is free to download once a profile account is created.

Operator certification is another risk management tool that should be considered part of drilling rig hazard mitigation. In 2017, the National Commission for the Certification of Crane Operators (NCCCO) began working with ADSC to develop a certification process for foundation drill rig operators. This certification is available through NCCCO.

Conclusions

Many drill rig incidents have been related to inadequate working platforms and improper use of equipment that violates manufacturer’s guidelines. Work is continuing to address these hazards through ANSI/ASSP consensus standards, certification processes, and other efforts. Regardless of the past efforts, more needs to be done to better understand these hazards and prevent these catastrophic events that can harm workers and the general public. Safety is without a doubt the most crucial investment we can make.

Peggy Hagerty Duffy, PE, DGE, is the Executive Director of ADSC.

Richard Marshall, CHST, is the Director of Safety for ADSC.

Douglas Trout, MD, MHS, is the Deputy Director, Office of Construction Safety and Health at NIOSH.

G. Scott Earnest, PhD, PE, CSP, is the Associate Director, Office of Construction Safety and Health at NIOSH.

[1] For example, five years of Bureau of Labor Statistics (BLS) Census of Fatal Occupational Injury data show that there were 25 deaths associated with drilling machines, and drilling augers and other machinery (source code 3241) from 2017-2021; however, BLS data specifically related to overturn injuries and fatalities are not available.

References

ADSC, DFI, PDCA Recommended Industry Practices for Safe Working Platforms for Construction Equipment (https://www.adsc-iafd.com/wp-content/uploads/2021/01/Working-Platforms-Document-1.pdf)

CFR 1926 Subpart CC – Cranes and Derricks in Construction

CFR 1926.1402 – Ground Conditions (https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.1402)

OSHA Letter of Interpretation regarding the term controlling entity and responsibility for ground conditions for safe crane operations – (https://www.osha.gov/laws-regs/standardinterpretations/2012-10-01)

California Construction Safety Orders, §1711. Reinforcing Steel and Post-Tensioning in Concrete Construction, (c) Site Access and Layout (https://www.dir.ca.gov/title8/1711.html)

Washington Labor and Industries WAC 296-155-680, Reinforcing Steel and Post-Tensioning Activities, Page 3, (7) Site access and layout

(https://apps.leg.wa.gov/wac/default.aspx?cite=296-155-680&pdf=true)

Regulation 345/15, Rotary Foundation Drill Rigs (https://www.ontario.ca/laws/regulation/r15345)

Posted on by