Preventing Struck-by Injuries in Construction: Lift Zone Safety

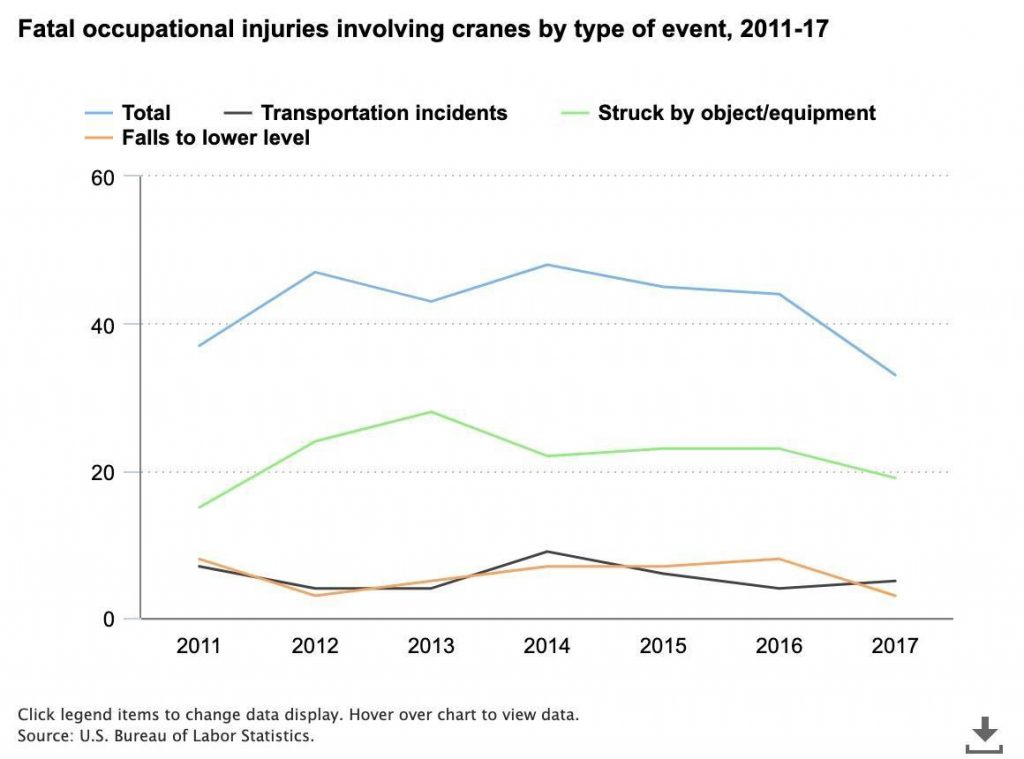

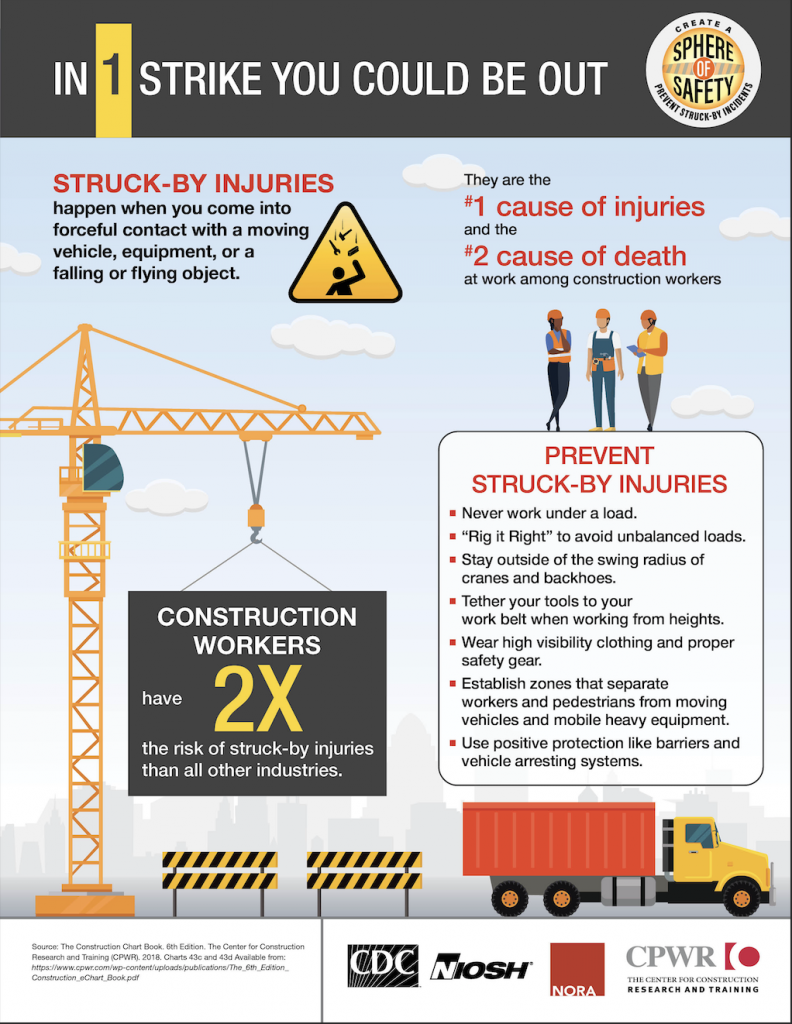

Posted on by The second annual National Stand-Down to Prevent Struck-by Incidents hosted by the NORA Construction Sector Council will take place April 26th, 2021, during National Work Zone Awareness Week (1). During this event, construction employers and employees will learn about best practices and methods to prevent struck-by incidents. Emphasis has been placed on the prevention of these types of incidents because they are the number one cause of injury and number two cause of death in the construction industry (2). In 2019, 32.8% of nonfatal injuries resulting in days away from work in construction were caused by contact with an object or equipment (3). Struck-by incidents encompass a variety of events from objects falling from unprotected edges to worker/machine impacts. In the construction industry, cranes are a central component of many operations which introduce hazards that may lead to struck-by incidents. As depicted in Figure 1, from 2011 to 2017, just over 50% of fatalities involving cranes in all industries were caused by a worker being struck by an object or equipment. In the same period, 43% of fatalities involving cranes occurred in the private construction industry compared to heavy civil construction, manufacturing and other industries (4). Employers and employees can work together to implement best practices for the prevention of struck-by incidents in lift zones (area near a crane’s load).

The second annual National Stand-Down to Prevent Struck-by Incidents hosted by the NORA Construction Sector Council will take place April 26th, 2021, during National Work Zone Awareness Week (1). During this event, construction employers and employees will learn about best practices and methods to prevent struck-by incidents. Emphasis has been placed on the prevention of these types of incidents because they are the number one cause of injury and number two cause of death in the construction industry (2). In 2019, 32.8% of nonfatal injuries resulting in days away from work in construction were caused by contact with an object or equipment (3). Struck-by incidents encompass a variety of events from objects falling from unprotected edges to worker/machine impacts. In the construction industry, cranes are a central component of many operations which introduce hazards that may lead to struck-by incidents. As depicted in Figure 1, from 2011 to 2017, just over 50% of fatalities involving cranes in all industries were caused by a worker being struck by an object or equipment. In the same period, 43% of fatalities involving cranes occurred in the private construction industry compared to heavy civil construction, manufacturing and other industries (4). Employers and employees can work together to implement best practices for the prevention of struck-by incidents in lift zones (area near a crane’s load).

Where should you start?

Employers and workers should start by understanding CFR 1926 Subpart CC which addresses the use of cranes and derricks in construction. Derricks are lifting devices that are commonly found on ships and docks. Subpart CC addresses multiple aspects of crane safety and potential hazards. The OSHA standard provides a framework for required safety measures that must be in place for all crane operations. Additional resources on the CPWR struck-by hazards webpage can help employers identify and implement best practices for lift zone safety that extend beyond the OSHA regulations.

What should employers and workers know to improve crane safety?

While there are specific training requirements for crane operators, previous studies have found that lack of training for all workers significantly contributes to incidents involving cranes (5, 6). All workers who are around crane operations must be adequately trained in identifying hazards and prevention strategies.

1. What are the hazards associated with different types of cranes?

Cranes come in a variety of different forms and configurations (e.g., mobile cranes, tower cranes, and bridge cranes). Due to crane design and use, each type of crane presents different hazards. For example, the greatest percentage of accidents are caused by crane overturn for mobile cranes, crane collapse for tower cranes, and worker struck for bridge cranes (7).

2. Who can assemble/disassemble a crane?

Only trained workers should assemble/disassemble cranes under the supervision of a qualified and competent person (defined in the OSHA standard). Trained workers must follow the manufacturers’ procedures for both assembly and disassembly.

3. What precautions should be taken when operations are near power lines?

In a study of crane accidents from 1992 to 2006, 32% of deaths were caused by overhead power line electrocutions (8). If any of the equipment, load, or load line could get within 20 feet of a power line at the maximum radius employers must implement interventions according to one of the three options in the OSHA standard. Additionally, all workers working with and around the crane should be trained on electrocution hazards and how to appropriately respond if an incident occurs.

4. Who should conduct inspections?

A trained and competent person should inspect equipment prior to and during use to ensure it is in safe operating condition. Although crane equipment is often rented, construction contractors and subcontractors should have inspection procedures in place to ensure the safety of their workers (9). A study of construction fatalities involving cranes from 1984-1994 found that the implementation of a crane inspection program could prevent many crane-related deaths (10).

5. What safety devices are required for operation?

Per the OSHA standard several safety devices are required:

- Crane level indicator

- Boom stops

- Jib stops

- Locks for foot pedal brakes

- Integral holding device/check valve for hydraulic jacks

- Rail clamps and rail stops for equipment on rails

Workers involved in crane operations should be familiar with these safety devices and how to properly use them.

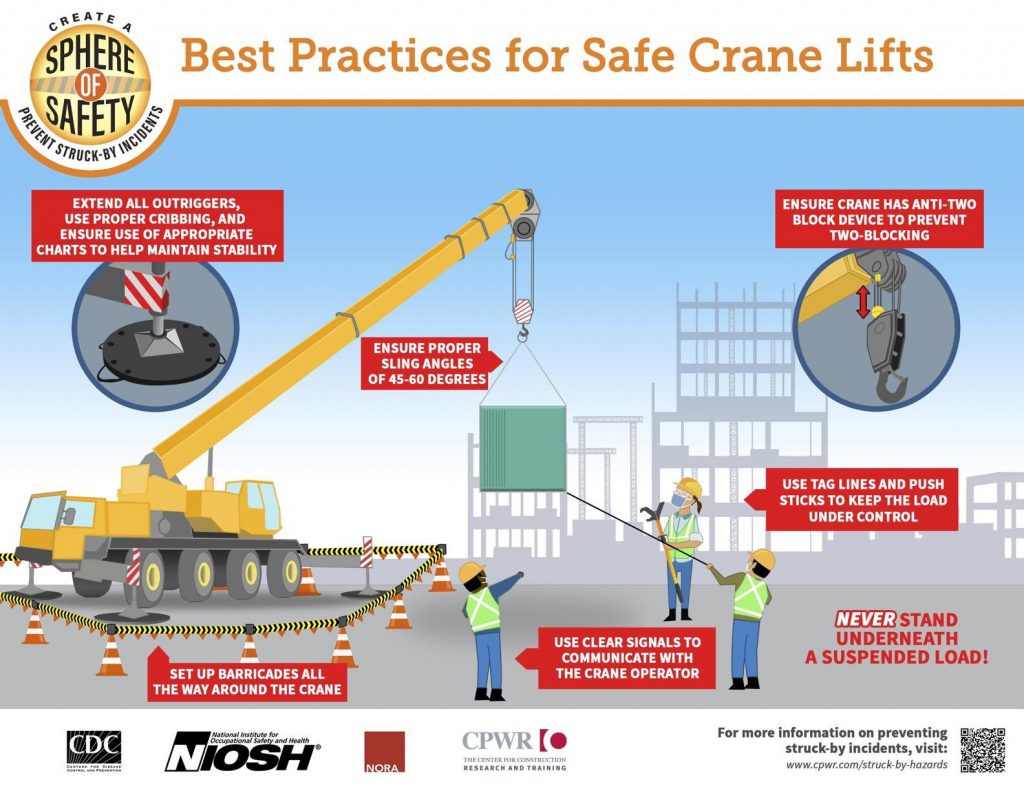

6. What practices should be in place while cranes are being operated?

Per the OSHA standard several operational practices are required:

- Operational Aids (e.g., boom hoist limiting device and automatic cessation of lifting device)

- Signals

- Work area controls

- Measures to prevent workers from being in the lift zone. Only essential workers are allowed in the lift zone but not under the load.

- Controls to prevent the public from entering the lift zone.

- Vehicular traffic controls.

7. What is safe rigging?

Proper rigging is critical to a safe crane operation. Analysis of crane-related fatalities in the construction industry indicated that 24 of 40 deaths from being struck by a load were caused by rigging failure (5). All workers in the rigging process should be trained in inspection protocols and principles of safe rigging. Safe rigging helps to ensure that material will not shift or dislodge during a lift. Many variables determine if a load is rigged properly and should be understood by all workers.

8) Who can perform maintenance tasks?

Only personnel that meet the definition of a qualified person in regards to the equipment and tasks should conduct maintenance. Maintenance personnel must understand how components interact and potential outcomes of improper maintenance. An effective preventative maintenance program should include all mechanical, electrical, and hydraulic systems (9).

9) What qualifications and certifications are required?

Operator – CFR 1926.1427(b)

“The employer must provide each operator-in-training with sufficient training, through a combination of formal and practical instruction, to ensure that the operator-in-training develops the skills, knowledge, and ability to recognize and avert risk necessary to operate the equipment safely for assigned work.”

Signal Person – CFR 1926.1428(c)

-

- Know and understand the types of signals used

- Know and understand the Standard Method for hand signals

- Show competency in the application of the types of signals used

- Demonstrate a basic understanding of equipment operations and limitations

- Know and understand the requirements of sections of Subpart CC that address signaling

- Demonstrate knowledge through a written test or practical exam

Spotter – CFR 1926.1401

Meets the qualifications of a signal person but has the sole responsibility to watch the separation between the power line and equipment.

Qualified Person – CFR 1926.1401

“A person who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training and experience, successfully demonstrated the ability to solve/resolve problems relating to the subject matter, the work, or the project.”

10) What training do workers around cranes need to have?

All workers around cranes should be trained in struck-by hazard identification and best practices to prevent these types of incidents. Many of these best practices can be found through the CPWR website linked above. The toolbox talks and infographics are a great way for leadership to introduce these topics in an interactive and discussion-based format.

What’s next?

What’s next?

Employers and workers should work together to take the appropriate measures to prevent struck-by incidents. In addition to all appropriate crane specific training, workers must be trained in the prevention of all struck-by injuries. The Center for Construction Research and Training (CPWR) has a variety of resources available to aid in this initiative.

The 2nd annual National Stand-Down to Prevent Struck-by Incidents will take place April 26th, 2021 — on the first day of Work Zone Awareness Week. Please try to join us for these events. The NORA Construction Sector Council will be holding two webinars as part of this virtual event (please be aware that the webinar platform only supports 1,000 people attending live, however everyone who registers for the event will automatically receive the recording).

Kyle Hancock is a contractor with the Office of Construction Safety and Health

Scott Earnest, PhD, PE, CSP, is the Associate Director for Construction Safety and Health.

Douglas Trout, MD, MHS, is a medical officer at NIOSH.

CDR Elizabeth Garza, MPH, CPH, is Assistant Coordinator for the Construction Sector in the NIOSH Office of Construction Safety and Health.

Resources

- Hoisting and Rigging Safety Manual (Infrastructure Health & Safety Association)

- NIOSH Alert

- CPWR Struck-by Hazards

- CPWR The Construction Chart Book

- Small Entity Compliance Guide for the Final Rule for Cranes and Derricks in Construction (OSHA)

References

- CPWR. Handouts, Planning Tools, & Training Programs: Struck-By Hazards. Available from: https://www.cpwr.com/research/research-to-practice-r2p/r2p-library/other-resources-for-stakeholders/struck-by-hazards/

- The Construction Chart Book. 6th Edition. The Center for Construction Research and Training (CPWR). 2018. Available from: https://www.cpwr.com/wp-content/uploads/publications/The_6th_Edition_Construction_eChart_Book.pdf

- CPWR. Data Bulletin: Nonfatal Injury Trends in the Construction Industry. Available from: https://www.cpwr.com/wp-content/uploads/DataBulletin-December2020.pdf

- Bureau of Labor Statistics. Fatal Occupational Injuries Involving Cranes (2011-2017). May 2019. Available from: https://www.bls.gov/iif/oshwc/cfoi/cranes-2017.htm#:~:text=From%202011%20to%202017%2C%2043,in%20the%20private%20construction%20industry.&text=Over%20half%20of%20these%20workers,in%20construction%20and%20extraction%20occupations

- Beavers, J. E., Moore, J. R., Rinehart, R., & Schriver, W. R. (2006). Crane-related fatalities in the construction industry. Journal of Construction Engineering and Management, 132(9), 901-910.

- Zhang, X., Zhang, W., Jiang, L., & Zhao, T. (2020). Identification of critical causes of tower-crane accidents through system thinking and case analysis. Journal of construction engineering and management, 146(7), 04020071.

- Milazzo, M. F., Ancione, G., Brkic, V. S., & Vališ, D. (2016). Investigation of crane operation safety by analysing main accident causes. Risk, Reliability and Safety: Innovating Theory and Practice, 74-80.

- CPWR. Crane-Related Deaths in Construction and Recommendations for Their Prevention. November 2009. Available from: https://www.cpwr.com/wp-content/uploads/publications/CPWR-Crane-Rept-Recmmdtns-Nov-2009-BLS-UPDATED.pdf

- Neitzel, R. L., Seixas, N. S., & Ren, K. K. (2001). A review of crane safety in the construction industry. Applied occupational and environmental hygiene, 16(12), 1106-1117.

- Suruda, A., Liu, D., Egger, M., & Lillquist, D. (1999). Fatal injuries in the United States construction industry involving cranes 1984-1994. Journal of occupational and environmental medicine, 41(12), 1052-1058.

Posted on by