Advancements in Elastomeric Respirator Technology for Use as Source Control

Posted on by

Respirator design is constantly improving and evolving to meet new challenges. Manufacturers have recently developed innovative NIOSH-approved elastomeric half mask respirator (EHMR) designs that both protect the wearer as well as provide adequate source control – protecting others by filtering the wearer’s exhaled air that may contain harmful viruses or bacteria.

EHMRs are being used more widely in U.S. healthcare systems because they can be cleaned, disinfected, and reused. During times when there are shortages of the filtering facepiece respirators (FFRs) typically worn in healthcare settings, EHMRs can help to meet this demand and alleviate the burden on the FFR supply. However, EHMRs traditionally have exhalation valves, which is a design feature that has caused concern about source control.

A respirator’s exhalation valve works by closing when the wearer inhales, pulling the inhaled breath through the filter material, and then opening to allow exhaled unfiltered breath to be expelled through the exhalation valve. This helps to reduce the overall breathing resistance, remove moisture, and reduce CO2 concentration and its effects, thereby increasing the user’s comfort, especially over a long period of time. A NIOSH-approved particulate respirator with an exhalation valve offers the same intended protection to the wearer as one without a valve. However, potential respiratory droplets expelled by wearers may exit along with air through the exhalation valve, which means that they may not provide efficient source control for use in certain healthcare settings, such as those requiring a sterile field. This limits how much traditional EHMRs with exhalation valves can be incorporated into healthcare systems to alleviate the supply shortage of FFRs.

Several NIOSH respirator approval holders have tackled this source control dilemma, developing new EHMR options that can both protect healthcare workers and be used in all healthcare settings. NIOSH has recently approved the first EHMR model without an exhalation valve. The Mine Safety Appliance Corporation (MSA) designed the Advantage 290, which provides P95 and P100 level protection to the wearer, as well as reduces the risk of spreading infectious diseases through expelled droplets in exhaled breath. This is because the air is being filtered in both directions. The lack of open exhalation valve forces the exhaled breath of air back out the same filter in which the air was breathed in.

Since this first approval, NIOSH also issued approval for Dentec Safety Specialists’ 400 NX series half mask respirators without exhalation valves. This includes the 400NXML, 400NXMDML, 400NXSM, and 400NXMDSM.

The 3M Corporation took a different approach to reduce the spread of infectious disease through respirators that have exhalation valves. 3M now offers an accessory filter that can be installed over the exhalation valve on their 6000 series of particulate-filtering EHMRs. This accessory filters the exhaled breath that passes through the exhalation valve. NIOSH has accepted this filter accessory as part of the approved 6000 model series respirator configuration. Its filtered exhalation valve provides source control similar to medical masks which are the products typically used in healthcare for source control.

NIOSH’S Contribution to the Science

In addition to the role of testing and certifying the effectiveness of these respirators for occupational use, NIOSH is contributing to the body of scientific knowledge in this area and fulfilling critical research needs to determine the potential for respirators with exhalation valve to be used as source control.

Exhaled Breath Filter Adaptors for Commercial Respirators

Based on their prevalent use in healthcare and a need to better understand the source control performance of EHMRs, NIOSH researchers used EHMR models from Honeywell International Inc., 3M, and MSA for a study on exhaled breath filter adaptors. This study was initiated to understand the effects of blocking an exhalation valve and directing the exhaled air back through the main (inhalation) filters, or, alternately, covering the exhalation valves externally with a surgical mask. The results from the study demonstrated that these EHMRs can be modified by blocking the exhalation valve and redirecting the exhaled breath though the main filters and still meet the NIOSH exhalation resistance performance requirement. However, there were increases in both the exhalation resistance and CO2 levels within the facepiece caused by modifying the respirators to filter the exhaled breath. NIOSH is working on designing and fabricating prototype filter housing adapters for select commercially available respirators with consideration to minimize any increases in exhalation resistance or CO2 concentrations inside these EHMRs.

Reusable Healthcare EHMRs

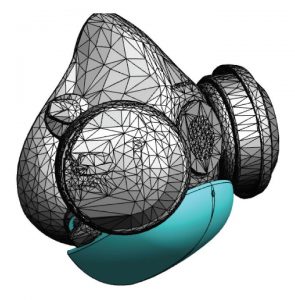

The objective of this project is to design and produce prototypes of reusable EHMRs specifically designed for healthcare delivery settings, meeting the specific needs of healthcare workers. The project commenced with input from stakeholders and examined the required features desired by healthcare workers in order to determine the best design direction. These respirators will consist of a half mask body incorporating an exhalation valve, filter attachment ports, and possibly a speech diaphragm. Based on the reported needs of healthcare workers, this respirator type must be low profile, ergonomically designed to allow the user a wide field of vision, have a comfortable head harness that is simple to put on, and be easily cleaned for reuse. It would incorporate an N95 particulate filter that would be discarded after use.

See the NIOSH NPPTL website for more information about NIOSH respirator exhalation valve research.

Rohan Fernando, M.S., is a Mechanical Engineer within the Research Branch of the NIOSH National Personal Protective Technology Laboratory.

Jeffrey Peterson is the Branch Chief of the Conformity Verification and Standards Development Branch in the NIOSH National Personal Protective Technology Laboratory.

Lee Portnoff, M.S., is a Biologist within the Research Branch of the NIOSH National Personal Protective Technology Laboratory.

Mention of any company, product, or service is for informational purposes only and does not constitute endorsement by the National Institute for Occupational Safety and Health (NIOSH), the Centers for Disease Control and Prevention (CDC), or the U.S. Department of Health and Human Services (HHS), or imply that any company or its products or services are preferred over any other.

Posted on by