A Guide to Respirators Used for Dust in Construction

Posted on by

Construction dust can cause serious damage to workers’ health and life-threatening diseases. Construction workers can be exposed to many types of dust, such as silica, wood, and lead dust. Workplace exposure to small particles of silica dust, also known as respirable crystalline silica, can lead to serious diseases, including silicosis, a progressive lung disease marked by scarring and thickening of the lung tissue; lung cancer; chronic obstructive pulmonary disease (COPD); and kidney disease. It’s estimated that about 2 million construction workers are exposed to silica dust on the job [CDC 2020].

NIOSH sets Recommended Exposure Limits (RELs), including a suggested limit of exposure to silica dust. A recent study of workers exposed to silica dust by industry published in the American Journal of Industrial Medicine found that of 100,000 workers who were exposed above the NIOSH REL, 8 out of 10 of those workers were in the construction industry [Doney et al. 2020].

Construction workers can be exposed to silica dust from many sources. For example, concrete workers can be exposed to silica dust during mixing, sawing, jackhammering, chipping, grinding, and cleaning operations. Masons can be exposed when cutting concrete blocks and bricks, mixing mortar, and tuckpointing. Tile workers can be exposed when cutting ceramic tiles or stone. Highway, street, and bridge construction workers can be exposed during abrasive blasting, drilling, milling, breaking, and cutting concrete. Site preparation workers can be exposed during earthmoving, excavation and trenching, and demolition, and drywall workers can be exposed when cutting drywall and sanding joints.

The Occupational Safety and Health Administration (OSHA) silica dust standard for construction requires employers to limit worker exposures to silica dust and protect them [29 CFR 1926.1153]. Table 1 in 29 CFR 1926.1153 has simplified the compliance process in construction by matching 18 common construction tasks with effective dust control methods and respiratory protection. Employers who use the controls specified in Table 1 are in compliance when they perform those tasks. If controls are not being used, or when performing tasks not listed in Table 1, employers are required to conduct air sampling to measure workers’ exposure to silica or obtain objective data to demonstrate that they comply.

In many cases, engineering controls are not adequate for safely controlling dust, and respirators must be used. A respirator is designed to protect workers from inhaling hazardous dusts when properly used. OSHA regulations govern the use of respirators in construction [29 CFR 1926.103]. If respirators are used, a respiratory protection program is required to ensure that they are used properly. OSHA mandates specific requirements for the use of respirators [29 CFR 1910.134(c)].

If your workplace is in compliance with dust standards, employers can permit workers to wear air-purifying respirators, following OSHA’s (Mandatory) Information for Employees Using Respirators When not Required Under Standard [1910.134 App D ]. Under this Appendix, the employer must meet the following OSHA requirements:

- Ensure proper respirator use and maintenance per manufacturer’s instructions.

- Ensure that only NIOSH-certified respirators are used and ones with the proper design for the application.

- Ensure that the exposure does not involve contaminants that the respirator is not designed to protect from. i.e., gases, vapors, or very small particles that the respirator will not collect.

- Keep track of the respirator to avoid using someone else’s.

Selecting the right air-purifying respirator requires an assessment of workplace operations, processes or environments that may create a respiratory hazard [NIOSH 2019].

Selecting a Respirator for Dust Control

NIOSH-approved air-purifying masks are available in two broad classes: non-powered and powered. Non-powered are sometimes referred to as negative-pressure respirators, and powered respirators are referred to as PAPRs (powered air-purifying respirators).

Non-powered air-purifying respirators

Several filter materials are available for negative-pressure respirators. Since some filters are degraded by oil mist, replaceable filter cartridges are designated according to their level of oil resistance, as follows:

- N-Series filters are not resistant to oil.

- R-Series filters are oil-Resistant up to one shift.

- P-Series filters are oil-Proof.

For mineral dusts, such as silica, any of these filters will work unless the workplaces has an oil mist source. The most common oil mist sources in construction comes from percussion drills. These workplaces should use type R or P filters. If oil mist is present, N-series filters will not be effective and should not be used. R-series filters should be used for one shift, and P-series filters should be changed in accordance with the manufacturer’s recommendations [NIOSH 1996].

The dust (or mist) collection efficiency of filter materials also varies. Filter cartridges are available in three efficiency levels: 95%, 99%, and 99.97%, designated as 95, 99, and 100. For example, an N95 filter is 95% efficient; an N99 filter is 99% efficient; and an N100 filter is 99.97% efficient.

The most commonly purchased filter types are N95s and P100s. Type 95 filters usually have a lower cost and breathing resistance than type 100 filters. As the letter rating and number rating increase, breathing fatigue will also increase.

Reusable half-masks and face-filtering respirators are non-powered negative-pressure respirators.

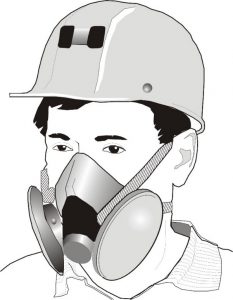

Reusable Half-Masks

A reusable half-mask, negative-pressure respirator, consists of a filter-holding unit called the facepiece or mask, fabricated from molded plastic or rubber. The mask contains intake and exhaust valves and is attached to straps that ensure a tight fit to the wearer’s face.

This type of half-mask respirator has a replaceable-filter that removes dust when the facepiece seal is leak-tight. The seal can occasionally cause skin irritation. These respirators also interfere with conversation and may interfere with eyeglasses or goggles.

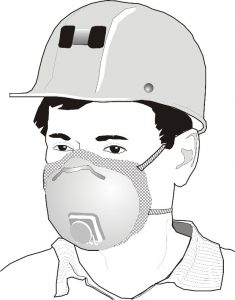

Filtering Facepiece Respirators (FFRs)

FFRs, commonly called dust masks are another type of negative pressure air purifying respirator. FFRs have a lighter design than half-mask respirators. The entire mask is fabricated from filter material that covers the mouth and nose.

FFRs offer some advantages compared to the replaceable-filter respirators. In particular, they are more comfortable and require no maintenance. It may be harder to pass a fit test with an FFR than a reusable half-mask. As a result, they are often much less effective than half-masks.

FFRs are certified by NIOSH under the 42 CFR 84 respirator certification tests. Certification is no guarantee that the mask will perform well as worn. In one study of FFRs [CDC 1998], the average dust reduction was only 67%.

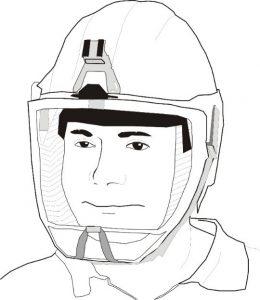

Powered Air-Purifying Respirators (PAPRs)

Powered air-purifying respirators (PAPRs) use a fan to draw air through the filter to the user. They are easier to breathe through than negative pressure air purifying respirators; however, they need a fully charged battery to work properly. PAPRs have three filter classes HE, PAPR100-N, and PAPR100-P. All three filter series must demonstrate a minimum efficiency level of 99.97 percent. It is important to know what the hazard is, and how much of it is in the air, to select the proper filters/cartridges.

PAPRs are often designed with a hard hat equipped with a battery-powered fan or a belt-worn battery and fan, filtering system, and face visor, thus providing protection for the head, lungs, and eyes and face within one unit. Another advantage is a lack of breathing resistance. Loose-fitting PAPRs have the ability to accommodate facial hair. Tight-fitting facepiece PAPRs are required by OSHA to be fit-tested and worn without facial hair.

The NIOSH Certified Equipment List (CEL) is a useful resource for making a respirator selection. The online CEL tool allows you to define search criteria based on characteristics of approved respirators.

Guidelines for Respirator Use

Respirator wearers should follow the manufacturer’s instructions. Comfort is as important as a tight seal. A worker may need to try different size respirators or respirators from different manufacturers before finding the best fit for his or her facial structure. Once a respirator is put on, positive and negative pressure seal checks are necessary to ensure there are no leaks that would degrade the respirator’s effectiveness.

Respirator maintenance

Basic respirator maintenance is simple. The wearer should check to ensure that the filter cartridges are undamaged, the inhalation and exhalation valves are in working order, no straps are slipping or broken, there are no tears or deformities in the facepiece, and the respirator is reasonably clean.

Regular replacement of filters is an important part of respirator use. Normally, filters should be replaced when breathing resistance increases and when they are damaged or soiled or at the end of the shift if exposed to oil mists. Another approach is to replace filters when the filter loading reaches 200 mg of dust [NIOSH 2018]. NIOSH has additional guidance on the reuse and extended use of filters: Filtering out Confusion: Frequently Asked Questions about Respiratory Protection, Respirator Reuse and Extended Use.

Many construction tasks can expose workers to hazardous dust. Protect your workers by selecting the appropriate respirator for the job and ensure it is used properly according to the manufacturer’s instructions and OSHA’s mandates. Keep your workforce safe and healthy.

CAPT Alan Echt, DrPH, CIH, Senior Industrial Hygienist in the NIOSH Office of Construction Safety and Health (retired).

Christopher Coffey, Ph.D, is the former Associate Director for Science for the NIOSH National Personal Protective Technology Laboratory (retired).

Scott Earnest, PhD, PE, CSP, is the Associate Director for Construction Safety and Health.

Jeanette Novakovich, MA, MS, PhD, is a Writer-Editor in the NIOSH Division of Science Integration.

CDR Elizabeth Garza, MPH, CPH, is Assistant Coordinator for the Construction Sector in the NIOSH Office of Construction Safety and Health.

Scott Breloff, Ph.D. is a Biomedical Research Engineer in the NOISH Office of Construction Safety and Health.

Christina Socias-Morales, DrPH, is a Research Epidemiologist in the NIOSH Office of Construction Safety and Health.

References

Centers for Disease Control and Prevention. Preventing silicosis. [topic page] U.S. Department of Health & Human Services. Centers for Disease Control. https://www.cdc.gov/features/preventing-silicosis/index.html

Doney BC, Miller WE, Hale JM, Syamlal G. Estimation of the number of workers exposed to respirable crystalline silica by industry: Analysis of OSHA compliance data (1979‐2015). Am J Ind Med. 2020;63:465–477. DOI:10.1002/ajim.23109

ISHN [2017]. ANSI/ASSE Z88.2 – 2015 practices for respiratory protection. Industrial Safety and Hygiene News. 2017, January. https://www.ishn.com/articles/105561-ansiasse-z882-2015-practices-for-respiratory-protection

Metzler RW, Johnson JS, Spelce DL, Rehak TR [2015]. What’s new in Z88.2 an introduction to ANSI/ASSE Z88.2-2015, practices for respiratory protection. The Synergist. https://synergist.aiha.org/201509-whats-new-in-z882

NIOSH [2018]. Filtering out Confusion: Frequently Asked Questions about Respiratory Protection, Respirator Reuse and Extended Use. By Shamblin M., Krah J., and Shaffer R. Pittsburgh, PA: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication 2018–128, https://doi.org/10.26616/NIOSHPUB2018128

NIOSH [1996]. Guide to the selection and use of particulate respirators certified under 42 CFR 84. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 96-101, 1996 Jan;1-29. https://www.cdc.gov/niosh/docs/96-101/

NIOSH [2019]. Mining Product: Dust Control Handbook for Industrial Minerals Mining and Processing. Second edition. Pittsburgh, PA: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2019-124 (RI 9701). https://www.cdc.gov/niosh/mining/works/coversheet2094.html

OSHA [2009]. Assigned protection factors for the revised respiratory protection standard. Washington, DC: U.S. Department of Labor, Occupational Safety and Health Administration. OSHA 3352-02. https://www.osha.gov/Publications/3352-APF-respirators.html

Posted on by