Are There Nano- and Microplastics in the Workplace?

Posted on by

The growing problem of plastic pollution in the environment is receiving an increasing amount of attention (see article in Nature). Small particles of plastics are often referred to as microplastics (plastic particles smaller than 5 mm [1]) and nanoplastics (the nanoscale fraction of plastic particles). Nano- and microplastic particles (NMPPs) can be formed through environmental and mechanical degradation (the top-down mechanism). They can be also generated through condensation of molecular species, for example, during heating or burning of plastics (the bottom-up mechanism).

A lot of attention is focused on the presence of NMPP in the food chain. A critical issue from an occupational health perspective is how workers might be exposed to NMPPs. Do they become airborne? If NMPP are airborne, the main route of exposure in the workplace is through inhalation.

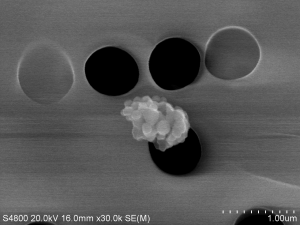

In the workplace, potential for inhalation exposure exists to nano- and microplastics generated through both the top-down and bottom-up mechanisms. In the top-down mechanism, NMPPs can be emitted during mechanical and environmental degradation of plastic goods which can lead to potential exposures to nano- and microplastics among workers in the waste management and recycling operations [6]. Degradation of carpets and other synthetic fiber products can produce airborne fibers considered NMPPs [14] with potential for exposure among office/teleworkers and custodial staff. Another example of a workplace process potentially leading to worker exposure is machining of polymer and plastic products generating dusts [7, 9]. In the bottom-up mechanism, NMPPs can be emitted during high energy or high heat processes (such as laser cutting or high-speed drilling), treatment of polymer composites, [2] and during 3D printing from melting or fusing of plastics [3, 4, 5, 8] (Figure 1). Workers in the facilities hosting plastic processers and printers could be exposed to airborne nano- and microplastic particles.

Toxicity of inhaled NMPPs is not well characterized in part due to the complexity of their chemical compositions and size and shape distributions and common association with other chemical hazards producing mixed exposures. For example, inhalation of thermal degradation products of polytetrafluoroethylene can lead to “polymer fume fever” [10] and in extreme cases to fatal acute pulmonary oedema [11]. These adverse health effects were associated with the presence of nanoscale particles comprised of decomposition products, including polymers, in the fumes, which can reach deep into the lung and access the pulmonary interstitium [12]. While pristine nanoplastic particles are relatively inert, when inhaled they can elicit an inflammatory response. Inflammation could be compounded by adverse biological response to chemicals and metals also in the particles (the “Trojan horse” mechanism).

NIOSH has been studying workplace aerosols since it was created in 1970. In those five decades, NIOSH helped with establishing methods to characterize aerosols including particle size and shape distribution, concentration, and chemical composition and to minimize exposure to them. Most recently the NIOSH Nanotechnology Research Center developed approaches for exposure measurement, assessment and mitigation, and hazard characterization for nanomaterials. Many of the approaches would also be applicable to characterize and minimize risk of nano- and microplastics in the workplace. For example, the NIOSH Nanotechnology Center demonstrated that existing exposure mitigation techniques such as local exhaust ventilation and High Efficiency Particulate Air filters effectively reduce concentration of airborne particles including those in the nanoscale [13].

Presently there are no occupational exposure limits for nano- and microplastics. In the absence of occupational exposure limits for nano- and microplastics workplace safety efforts should focus on minimizing potential exposure through appropriate engineering controls such as isolation cabinets, exhaust ventilation, and utilizing good industrial hygiene practices.

NIOSH is engaged with its government partners to better understand potential exposures to nano- and microplastics in the workplace, their hazards, and tools to minimize exposures.

We welcome your feedback. Are there instances where nano- or microplastics might be a source of potential exposures in your workplace?

Vladimir Murashov, PhD, is a Senior Scientist in the NIOSH Office of the Director.

Charles L. Geraci, Jr., PhD, CIH, FAIHA; is Associate Director for Emerging Technologies in the NIOSH Office of the Director.

Paul Schulte, PhD, is the Director of the NIOSH Division of Science Integration.

John Howard, MD, is the Director of the National Institute for Occupational Safety and Health.

References

[1] Gigault J., et al. Current opinion: What is a nanoplastic? Environmental Pollution, 2018, 235, 1030-1034.

[2] Walter J., et al. Analysis of potentially hazardous substances emitted during laser processing of carbon fiber reinforced plastics. Lasers in Manufacturing Conference 2015.

[3] Stefaniak A.B., et al. Particle and vapor emissions from vat polymerization desktop-scale 3-dimensional printers. Journal of Occupational and Environmental Hygiene, 2019, 16(8), 519-531.

[4] Stefaniak A.B., et al. Insights into emissions and exposures from use of industrial-scale additive manufacturing machines. Safety and Health at Work, 2019, 10, 229-236.

[5] https://blogs.cdc.gov/niosh-science-blog/2018/08/16/3d-printing/

[6] Wohlleben W., et al. Elastic CNT-polyurethane nanocomposite: synthesis, performance and assessment of fragments released during use. Nanoscale, 2013, 5, 369.

[7] Zimmer A.T., Maynard A.D. Investigation of the Aerosols Produced by a High-speed hand-held grinder using various substrates. Annals of Occupational Hygiene, 2002, 46, 663.

[8] Stefaniak A.B., et al. Three-dimensional printing with nano-enabled filaments releases polymer particles containing carbon nanotubes into air. Indoor Air, 2018, 28, 840.

[9] Ding Y., et al. Nano-object release during machining of polymer-based nanocomposites depends on process factors and the type of nanofiller. Annals of Work Exposures and Health, 2017, 61, 1132.

[10] Williams N., et al. Polymer fume fever: not so benign. Journal of Occupational Medicine, 1974, 16, 519.

[11] Lee C.H., et al. Fatal acute pulmonary oedema after inhalation of fumes from polytetrafluoroethylene (PTFE). European Respiratory Journal, 1997, 10, 1408.

[12] Ferin J., Oberdörster G. Polymer degradation and ultrafine particles: Potential inhalation hazards for astronauts. Acta Astronautica, 1992, 27, 257.

[13] NIOSH [2013]. Current strategies for engineering controls in nanomaterial production and downstream handling processes. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2014–102.

[14] Dris, R.; Gasperi, J.; Mirande, C.; Mandin, C.; Guerrouache, M.; Langlois, V.; Tassin, B. A first overview of textile fibers, including microplastics, in indoor and outdoor environments. Environ. Pollut. 2017, 221, 453−458.

Posted on by