Wearable Technologies for Improved Safety and Health on Construction Sites

Posted on by

Background

Wearable technologies are an increasingly popular consumer electronic for a variety of applications at home and at work. In general, these devices include accessories and clothing that incorporate advanced electronic technologies, often with smartphone or ‘internet of things’ (IoT) connectivity. While wearables are increasingly being used to improve health and well-being by aiding in personal fitness, innovative applications for monitoring occupational safety and health risk factors are becoming more common. Many of these devices have reached the market while others are still in development. As more wearables become available, they have the potential to positively impact and alter the landscape of society and work as we know it [Awolusi et al 2018].

Construction

Construction sites are dynamic environments with unique and often hazardous working conditions that can change daily and throughout the life of a project. Nearly 20% of all work-related fatalities in any given year occur on construction sites, yet the industry only hires about six percent of the U.S. workforce [CPWR 2018]. These environments frequently expose workers to extreme temperatures, loud noises, poor air quality, and job-related tasks are regularly performed in close quarters. Often, heavy construction equipment is operating in proximity to ground workers, creating potential hazards for collisions between workers and construction vehicles [CPWR 2018]. The temporary nature of construction sites and project organization make the use of many standard industrial monitoring systems impractical. These and other factors are creating a growing demand for wearable technologies.

Wearable technology is beginning to be developed, tested, and used for a variety of applications in construction. For example, proximity detection and alert systems, used as a wearable technology, are reliable and effective and have the potential to warn workers on the ground or operating equipment when moving hazards such as heavy construction equipment is near. Physiological status monitors can reliably collect worker data in the outdoor environment and warn about the potential for heat stress. Environmental sensors can be used to monitor air quality, including carbon monoxide, hydrogen sulfide, gas leaks, temperature, humidity, and noise. Exoskeletons can be used for reducing the mechanical stress of manual labor. (See related blog).

Wearable devices and the related sensors are now available in many forms including clothing, watches, helmets and eyewear. Advances in miniaturized sensors and wireless technologies are permitting a new generation of protective equipment to become reality. These types of devices have been used to reduce exposures to hazardous conditions. A few examples follow:

- By combining sensors with location or video information, specific work tasks can be evaluated as a potential source of exposure. Direct-reading and sensor technologies can monitor exposure to harmful chemicals or substances and empower workers to have a better understanding of their work environment (EVADE video on YouTube channel). These technologies can help workers, employers, and supervisors reduce harmful workplace exposures and become active partners in preventing occupational illnesses and injuries.

- A worker wearing an exoskeleton can reduce the physical load on their body and potentially prevent some musculoskeletal disorders. In a study of forward bend lifting using an exoskeleton intended to decrease spine loading and improve posture, researchers found that exoskeletons decrease total work, fatigue and load while also improving posture [NIOSH 2016; NIOSH 2019]. In addition to decreasing load on the spine, exoskeletons are able to decrease shoulder discomfort while increasing productivity and work quality in painters and welders. (See related blog).

- A worker wearing a proximity sensor can be notified if a piece of heavy equipment is approaching him. Likewise, smart vehicles can monitor workers in their vicinity [Narla 2013].

Additionally, active monitoring of physiological data with wearable technologies may allow for the measurement of heart rate, breathing rate, and posture [Nath et al 2017]. This type of real-time information can help workers actively monitor their bodies’ response to the work environment and its demands. Among other engineering application areas, automatically monitoring the location and movement of people can be useful for safety, security, and process analysis. When used on worksites, wearable devices are often connected to a wireless mesh infrastructure via an IoT network. This network is the backbone of the system, and allows for integration of the physical world into the network. The IoT network can also be connected to a computer for monitoring and analytics. This set-up allows for messaging, warnings, and alarms in addition to monitoring location.

NIOSH Efforts

NIOSH continues to work on wearable technologies that have applications to construction, as well as other industry sectors. Much of NIOSH’s past research in this area has addressed the use of wearables for evaluating personal exposure to airborne contaminants. Work continues in this area, and the research often involves a progression of steps from small hand portable devices involving discrete electronics to wearables. For example, in some cases tools can be miniaturized, but they may not be wearable yet. Making devices small and functional enough to be worn can in many cases take considerable time. NIOSH research topics that are relevant include personal dust monitors such as the continuous personal dust monitor (CPDM), direct reading welding fume instruments [Diwakkar et al. 2012] and end of shift silica measurement [Lee et al. 2017]; as well as, development of a lab-on-a-chip for silica exposure [Upaassana et al. 2019]. These technologies and applications are promising and have the potential to have benefits that could positively transform the industry. Many of these devices can be integrated into existing wellness programs to support a Total Worker Health® approach to safety.

The NIOSH National Construction Center – CPWR has conducted research on wearable warning systems and embedded safety communication devices to protect workers from struck-by incidents related to vehicle movement and intrusions in construction work zones [CPWR 2019]. NIOSH has also conducted research on tag-based systems that can be worn by construction workers to alarm them of potential vehicular hazards [Pratt et al 2001; Ruff et al 2004]. Significant work is also occurring at NIOSH to understand the potential benefits and risks of exoskeleton use. This work is looking at reducing musculoskeletal disorders, vibration, and the potential impact on falls.

Barriers to Wider Adoption

Cost, maintenance, and privacy are all issues that could affect how widely these technologies are adopted. Many of these systems require infrastructure spending, such as an IoT mesh network, in addition to the cost of the wearable devices. Costs vary widely depending upon the technology. Individual sensors can cost as little as $35 (Bluetooth device) to over $1,000 (Radio frequency identification-RFID).

In many cases, more research is needed to fully understand the impact these new technologies have on the workforce. Some groups have expressed concerns that wearables could be used for productivity monitoring or that a company could use a device to track an employee’s location, hours worked, breaks, and even their number of steps during the day. Fortunately, in many cases it is possible to set up a system that keeps the user information anonymous.

What construction hazards do you think could benefit from wearable technology? If you have used any of the technologies described in this blog please share your experiences in the comment section below.

Scott Earnest, PhD, PE, CSP; CAPT Alan Echt, DrPH, CIH; and CDR Elizabeth Garza, MPH, CPH, work in the NIOSH Office of Construction Safety and Health.

John Snawder, PhD, DABT, is a Research Toxicologist in the NIOSH Health Effects Laboratory Division and Co-Director of the NIOSH Center for Direct Reading and Sensor Technologies.

Rick Rinehart, ScD., is the Deputy Director at CPWR – The Center for Construction Research and Training.

NOTE: This science blog was developed through a collaboration between a NORA Construction Sector Council workgroup and the NIOSH Center for Direct Reading and Sensor Technologies.

References

Awolusi, I., Marks, E., Hallowell, M. (2018) Wearable technology for personalized construction safety monitoring and trending: Review of applicable devices. Automation in Construction. 85: 96-106.

Choi, B., Hwang, S., Lee. S. (2017) What drives construction workers’ acceptance of wearable technologies in the workplace? Indoor localization and wearable health devices for occupational safety and health. Automation in Construction. 84: 31-41.

CPWR (2018) The Construction Chartbook. Fifth Ed. CPWR- the Center for Construction Research and Training. Silver Spring, MD. http://www.cpwr.com/publications/construction-chart-book

CPWR (2019) Embedded Safety Communication System for Robust Hazard Perception of Individuals in Work Zones. CPWR- the Center for Construction Research and Training. Silver Spring, MD.

Diwakar, P, Kulkarni, PS, Birch, ME. New Approach for Near-Real-Time Measurement of Elemental Composition of Aerosol Using Laser-Induced Breakdown Spectroscopy Aerosol Sci Tech 2012 Mar; 46(3):316-332.

Konda, S., Tiesman, HM, Reichard, AA. (2016) Fatal Traumatic Brain Injury in the Construction Industry, 2003-2010. AJIM. 59:22-220.

Lee, T. Lee, L., Cauda, E., Hummer, J., Harper M. (2017) Respirable size-selective sampler for end-of-shift quartz measurement: Development and performance, Journal of Occupational and Environmental Hygiene, 14:5, 335-342.

Narla, SRK (2013) The Evolution of Connected Vehicles Technology: From Smart Drivers to Smart Cars to… Self-Driving Cars. ITE Journal. July. 22-26.

Nath, N, Akhavian, R, Behzadan A. (2017) Ergonomic analysis of construction worker’s body postures using wearable mobile sensors. Applied Ergonomics. 62. 107-117.

NIOSH (2019) Proceedings of the 2018 Ergo-X Symposium: Exoskeletons in the Workplace — Assessing Safety, Usability, and Productivity. By Lowe B, Billotte W, Brogmus G, McDowell T, Reid C, Rempel D, Srinivasan D (Editors). Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2020-102, https://doi.org/10.26616/NIOSHPUB2020102.

NIOSH Science Blog (2016). Wearable Exoskeletons to Reduce Physical Load at Work. https://blogs.cdc.gov/niosh-science-blog/2016/03/04/exoskeletons/

NIOSH Science Blog (2018). Improving Occupational Safety and Health in the Construction and Mining Industries. https://blogs.cdc.gov/niosh-science-blog/2018/05/31/construction-mining-osh/

NIOSH Science Blog (2017). Wearable Sensors: An ethical framework for decision making. https://blogs.cdc.gov/niosh-science-blog/2017/01/20/wearable-sensors-ethics/

Overview of Proximity Warning Technologies and Approaches. Todd Ruff, NIOSH, September 2010. https://www.cdc.gov/niosh/mining/UserFiles/workshops/proximityworkshop2010/Ruff-NIOSH-PDWorkshop2010-508.pdf

Pratt, S. G., Fosbroke, D.E., and Marsh, S.M. (2001). Building Safer Highway Work Zones: Measures to Prevent Worker Injuries from Vehicles and Equipment, Department of Health and Human Services: CDC, NIOSH, 5-6.

Roja, P, Srihari D. 2018. IOT Based Smart Helmet for Air Quality Used in the Mining Industry. IJSRET. 4(8) 514-521.

Ruff, T.M. (2004). Advances in Proximity Detection Technologies for Surface Mining. Proceeding of the 24th Annual Institute on Mining Health, Health, Safety and Research, Salt Lake City.

Stewart, M., Teizer, J., Reynolds, M. (2011). SmartHat: A Battery-free Worker Safety Device Employing Passive UHF RFID Technology, RFID 2011, Orlando, Florida.

Teizer, J., Golovina, O., Wang, D., and Pradhananga, N. (2015). “Automated Collection, Identification, Localization, and Analysis of Worker-Related Proximity Hazard Events in Heavy Construction Equipment Operation”, 32nd ISARC, Oulu, Finland.

Upaassana, VT, Ghosh, S., Chakraborty, A, Birch, ME, Joseph P, Han, J, Ku B, Ahn, CH. (2019) Highly Sensitive Lab on a Chip (LOC) Immunoassay for Early Diagnosis of Respiratory Disease Caused by Respirable Crystalline Silica (RCS) Analytical Chemistry 6652-6660.

Wang, D., Chen J, Zhao D, Dai F, Zheng C, Wu X. (2017) Monitoring workers’ attention and vigilance in construction activities through a wireless and wearable electroencephalography system. Automation in Construction 82 122-137.

Wearable Mobile Solutions to Improve EHS and Performance Management. IHSN. July 6, 2017. https://www.ishn.com/articles/106836-wearable-mobile-solutions-to-improve-ehs-performance-management

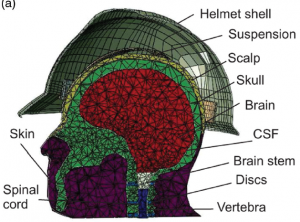

Wu, JZ, Pan CS, Wimer BM, Rosen CL. (2017) Finite Element Simulations of the Head-Brain responses to the Top Impacts of a Construction Helmet: Effects of the Neck and Body Mass. J of Engineering in Medicine. 231(1) 58-68.

Posted on by